Revolutionizing Lab Precision: Mastering the Multifunctional Small Vacuum Automatic Coating Machine for Cutting-Edge Research

2025-11-29 14:45Imagine stepping into a bustling lab where every second counts, and precision isn't just a goal—it's the lifeline of groundbreaking discoveries. Enter the Multifunctional Small Vacuum Automatic Coating Machine: a compact powerhouse that packs advanced vacuum technology into a space-saving design tailored for modern labs. This isn't your grandfather's coating setup; it's a smart, automated solution that delivers flawless thin films for everything from battery electrodes to optical lenses. Whether you're scaling up prototypes or fine-tuning experiments, this lab vacuum coating equipment promises to elevate your results. Let's dive in and explore why this machine deserves a spot on your bench.

What Exactly Is a Multifunctional Small Vacuum Automatic Coating Machine?

You know that moment when a tool feels like an extension of your hand? That's the vibe with the Multifunctional Small Vacuum Automatic Coating Machine. At its heart, this device creates ultra-thin, uniform coatings on substrates under a controlled vacuum environment. It automates the entire process—from substrate loading to deposition and unloading—making it ideal for labs where space and time are at a premium.

Shykejing designs this lab vacuum coating equipment with versatility in mind. It handles multiple coating methods, like magnetron sputtering and thermal evaporation, all in one unit. Automated controls adjust parameters like deposition rate, temperature, and gas flow, ensuring repeatability every time.

Drawing from our years at Shykejing, we've refined this lab vacuum coating equipment based on feedback from global installations. It builds on proven vacuum principles—think high-energy particle beams vaporizing source materials onto your substrate—but amps them up with user-friendly interfaces. No more manual tweaks under dim lights; the touchscreen dashboard lets you program recipes and monitor in real-time. As a result, teams report up to 40% faster turnaround on coating runs, freeing you to focus on innovation rather than fiddling with dials.

Key Technical Features That Drive Superior Performance:

What sets our Multifunctional Small Vacuum Automatic Coating Machine apart in the crowded world of lab vacuum coating equipment?

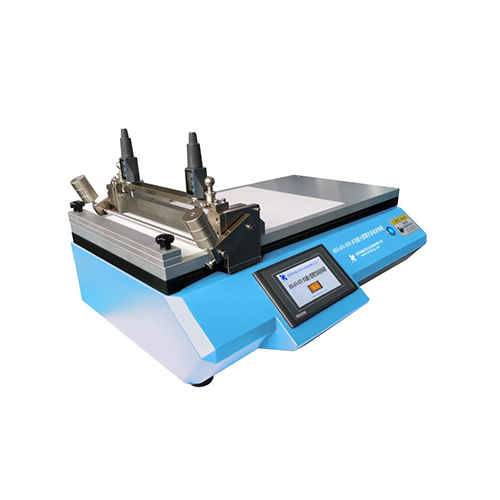

The biggest advantage of the lab vacuum coating equipment is its ability to perform coating experiments on various flat materials such as paper, plastic, metal, PVC, PET, fabric, and aluminum alloy plates. The MSK-AFA-IVDV multi-functional small vacuum automatic coating machine's greatest advantage lies in its ability to repeatedly and continuously produce smooth, flat, and flawless test samples. This allows researchers to accurately coat different substrates, reducing or eliminating errors caused by human factors such as variations in coating speed and pressure.

It's the fusion of cutting-edge tech with battle-tested reliability. At Shykejing, we pour decades of expertise into every component, ensuring you get equipment that performs like a pro while feeling intuitive for everyday use.