Differences Between a Vibratory Sander and a Polishing Machine

2025-12-25 10:05Many people find it difficult to distinguish between a vibratory sander and a polishing machine. At first glance, both are used to treat the surface texture of materials, but in fact, the two types of equipment differ fundamentally in working principles, processing results, and application scenarios.

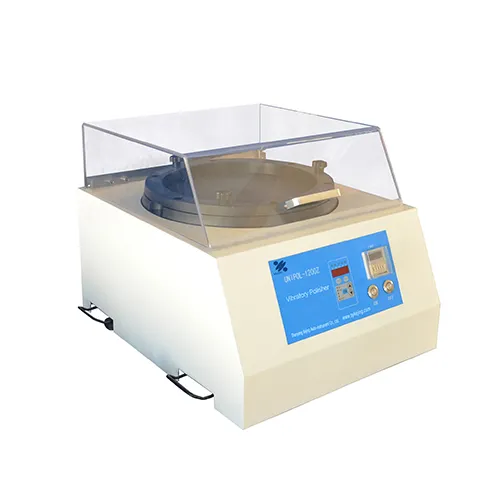

Working Principle of Polishing machine:

A vibratory sander relies on a high-speed moving sanding belt or sanding disc to generate friction, removing surface impurities through abrasive particle cutting. Common electric or pneumatic vibratory sanders produce a large amount of dust during operation, so materials such as metal and wood must be used in conjunction with dust extraction systems. A Polishing machine uses fine polishing discs combined with polishing compounds, achieving surface refinement and filling at the molecular level through high-speed rotation. It produces little dust but generates continuous heat; excessive temperature can burn the working surface, so water-cooling or air-cooling systems are required.

Differences in Material Processing Stages:

Sanding belongs to the rough processing stage. Rust on metal surfaces, residual putty after paint removal, excess glue and raised holes on assembled wooden products all require initial leveling with a vibratory sander. Floors in newly built commercial housing must first be sanded to level uneven walls before applying wall paint. In handmade leather goods production, coarse-grit sanding equipment is also required to treat rough edges at leather joints before entering the dyeing stage.

Polishing is performed at the end of the processing chain. Hardware products must undergo mirror polishing after welding and assembly before they can be sold. After vehicle color wrapping, full-vehicle polishing is needed to eliminate bubbles and halos in the film layer. Injection-molded parts removed from molds often show flow marks and shrinkage, which must first be sanded and then finally polished. In the nail art industry, after shaping the nail surface, miniature polishing devices are used to adjust surface gloss.

Professional automotive painting practices confirm that over 90% of auto repair shops use a process of first sanding body filler with a dual-action vibratory sander and then switching to a Polishing machine to treat the clear coat surface. Jewelry polishing cases show that precious metal jewelry, after being shaped by milling cutters, must undergo pre-polishing with eight different grit sandpapers before being transferred to polishing wheels for mirror finishing of precious metals.

Physical Appearance Comparison:

Wood treated with sandpaper below 180 grit shows obvious horizontal spiral marks, forming uniform fingerprint-like track structures. With increased operating pressure, pits of varying depth may appear. Polishing results after wet sanding processes above 320 grit only show subtle fibrous textures with differences in light reflection. After metal polishing, mirror-like reflections can be formed under 30-degree angled lighting; for example, a brass rod that has undergone six rounds of fine polishing can fully reflect the inspector’s work badge image on its surface.

Differences in Operational Details of Polishing machine:

Equipment adjustment precautions: before operating a vibratory sander, material thickness must be confirmed. Metal work surfaces should use automatic pressure-regulating sanding machines with pneumatic lifting functions to prevent jamming and surface penetration. When adjusting a Polishing machine, appropriate rotational speed must be selected based on material ductility. Aluminum alloys are recommended to be polished at speeds below 400 rpm with red solid polishing wax, while stainless steel requires adjustment to around 600 rpm with ceramic microcrystal polishing compounds. Common industrial accident statistics show that improper operation of small handheld vibratory sanders can lead to metal dust explosions, accounting for 7% of typical workplace injury cases, while burns caused by polishing machines are mainly due to prolonged stationary operation.

Abrasive and Consumable Systems of Polishing machine:

Common sanding belts on the market are divided into four types: kraft paper sandpaper offers optimal efficiency for wood surfaces, with a service life twice that of cloth-backed sandpaper. Resin composite sanding meshes with anti-static functions effectively prevent aluminum powder accumulation and short circuits that can cause equipment self-ignition accidents. High-end models are compatible with zirconia alumina closed-coat sanding belts featuring self-cleaning dust-removal groove structures. Precision polishing must be matched with a four-stage particle size material system.