Precision Polishing Fixture For Dia.80mm Sample

GPC-80A Precision Grinding and Polishing Controller (lapping controller for short), is mainly used to control the flatness and parallelism of sample surface, so that the polished sample has high dimensional accuracy and excellent surface condition. It is mainly suitable for using in UNIPOL-1202 and UNIPOL-802 grinding and polishing machines. It is especially suitable for grinding and polishing Geological thin sheets.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction

The GPC-80A Precision Grinding and Polishing Controller, referred to as the polishing controller, is primarily used to control the flatness and parallelism of the surfaces of samples being ground and polished, ensuring high dimensional accuracy and excellent surface quality. The controller is made of high-quality stainless steel, featuring an elegant appearance and exquisite craftsmanship. It is mainly used with UNIPOL-1202 and UNIPOL-802 precision grinding and polishing machines and is an indispensable precision tool during the grinding and polishing of workpieces, particularly suitable for the grinding and polishing of geological thin section samples.

The GPC-80A Precision Grinding and Polishing Controller comes with a dedicated sample holder block that connects to the controller via threads. Samples are mounted on the holder block using an adhesive method. The holder can accommodate samples with a diameter of ≤3 inches and a thickness of ≤9mm, offering the advantage of high process repeatability.

Main Features

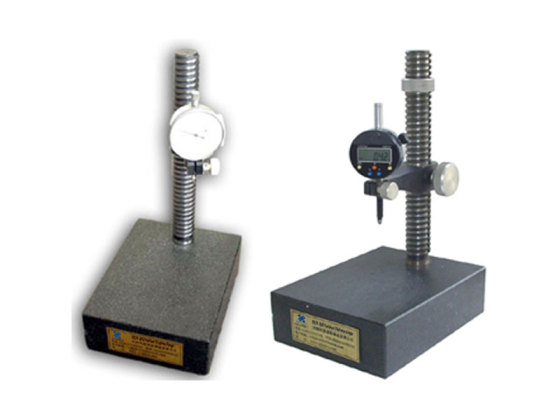

The parallelism and flatness of sample surface can be strictly controlled with high control accuracy. During the grinding process, it can be used with a digital thickness gauge to observe the grinding amount of the sample at any time. It is especially suitable for sample grinding with high requirements on surface parallelism, flatness and sample thickness.

Technical Parameters

Product Name | GPC-80A Precision Grinding and Polishing Controller | |

Product Model | GPC-80A | |

| Installation Conditions | 1. Temperature & Humidity: 10–85%RH (at 25℃, non-condensing); Temperature: 5–45℃. 2. The equipment should be placed in an environment free from strong vibration sources and corrosive gases. 3. Water Supply: A clean water source should be available on site (for equipment cleaning only). 4. Air Supply: Not required. 5. Ventilation: Good ventilation environment; no special ventilation equipment required. | |

Main Parameters (Specification) | 1. Sample Holder Diameter: Ø80mm 2. Axial Travel of Sample Holder: 9mm 3. Partial No-Load Pressure of Sample Holder: 750g 3. Counterweights: 100g each × 4, total 400g 4. Indexing Nut (Index Plate): 5. Digital Micrometer: Resolution 0.001mm, Range 0–12.7mm (Max) 6. Sample Mounting Method: Standard holder — adhesive mounting 7. Supported Sample Size: Diameter ≤3 inches, Thickness ≤9mm | |

Product Dimension | 8. Product Specifications: · Dimensions: Outer diameter 117mm; Height without counterweight 155mm, Height with counterweight 204mm |

|

Optional Accessories

| No. | Name | ||

| 1 | Counterweights(≥50g、≤200g) | Optional | - |

| 2 | HEATER-250/3040 Series Heating Platform | Optional |  |

Logistics