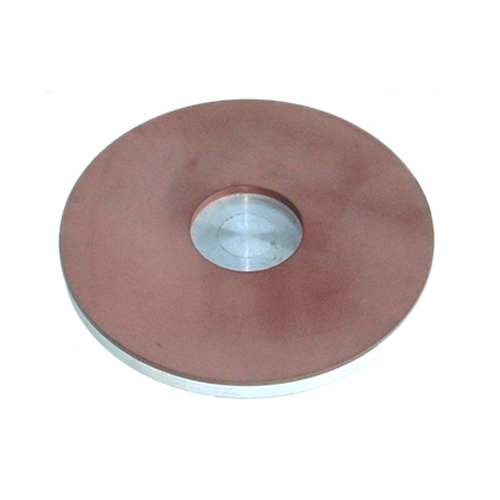

Magnetic Resin Diamond Grinding and Polishing Disc

1. This Diamond grinding and polishing disc is an accessory for our UNIPOL series grinding and polishing equipment and can be customized according to different machine models.

2. Our Diamond grinding and polishing discs are tested before leaving the factory, ensuring fast and precise grinding, accelerating your experimental progress.

3. Our Diamond grinding and polishing discs are compatible with various materials, enabling integrated operation and reducing wasted time.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 1000pcs

- Information

Introduction of Professional diamond polishing disc:

The Professional diamond polishing disc is a multi-functional grinding consumable that combines efficient grinding and fine polishing. It is widely used in our UNIPOL series grinding and polishing equipment. Made from a composite of resin matrix and high-quality diamond abrasive, combined with a metal magnetic backing plate, the Professional diamond polishing disc possesses excellent wear resistance and grinding strength. The Magnetic resin diamond grinding disc can be directly attached to the grinding disc surface, making installation faster and use more convenient.

This Magnetic resin diamond grinding disc is suitable for processing a variety of high-hardness and brittle materials, such as crystalline materials, ceramics, cemented carbide, optical glass, gemstones, and diamond crystals. Different grit sizes of the Magnetic resin diamond grinding disc can be selected according to process requirements, enabling integrated operation from rough grinding to fine polishing. Without the need for liquid abrasives, the Magnetic resin grinding and polishing disc effectively reduces abrasive consumption and cleaning costs, improving overall processing efficiency and sample surface quality.

Product Technical Parameters:

| Product Name: | Magnetic Resin Diamond Grinding and Polishing Disc |

| Product Parameters: | 1. Grit Sizes: 80#, 120#, 150#, 180#, 240#, 320#, 400#, 500#, 600#, 800#, 1200#, 1500#, 1800#, 2000# 2. Diameter: Ø150mm, Ø200mm, Ø250mm, Ø300mm, Ø320mm, Ø381mm |

Advantages of Magnetic resin grinding and polishing disc:

The Magnetic Resin Grinding and Polishing Disc features a metal magnetic backing plate design, eliminating the hassle of traditional adhesive or mechanical fastening. It attaches instantly, allowing for disc changes in seconds, significantly reducing downtime and improving experimental efficiency during multi-step grinding processes.

The magnetic attachment provides not only secure installation but also convenient disassembly, cleaning, and storage, preventing adhesive residue from contaminating the disc surface and extending the lifespan of the consumables.

We offer a full range of grit sizes from coarse grinding 80# to fine grinding 2000#.

With diameters covering Ø150mm - Ø381mm, it perfectly fits our UNIPOL series equipment and is also compatible with most mainstream grinding and polishing machines on the market, meeting the processing needs of different sample sizes.

Why choose us?

1. Original Equipment Manufacturer (OEM) Matching, Optimal Performance:

This grinding disc is specifically developed for our UNIPOL series grinding and polishing equipment. Choosing original consumables means that the disc's weight, magnetic strength, and dynamic balance have undergone rigorous matching tests with the equipment's rotation speed and pressure system. "A good horse deserves a good saddle," maximizing the processing accuracy of the equipment and extending the lifespan of the spindle.

2. Many customers don't know what speed or pressure to use with their grinding discs. Because we understand the materials, our expert team can provide you with specific process parameter recommendations. For example, for zirconia ceramics, we will tell you what grit size to start with and what pressure setting to use, helping you skip the trial-and-error phase and directly obtain perfect samples.

3. As a frequently used consumable, stability is crucial. We guarantee that the diamond concentration and resin hardness of each batch of grinding discs are uniform, ensuring that your experimental data from three months ago is repeatable three months later. We also maintain a constant inventory to ensure that your research progress is not interrupted due to a shortage of consumables.