Laboratory Simulation Battery Low Voltage Test Machine

1. The Vacuum Chamber with Programmable Pressure Control is designed for battery altitude simulation testing based on UN 38.3 (38.3.4.1).

2. The Vacuum Chamber with Programmable Pressure Control can be used as a vacuum storage chamber to automatically control the vacuum pressure.

3. The Vacuum Chamber with Programmable Pressure Control is made of stainless steel plate, which can effectively prevent explosion.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of Vacuum Chamber for Battery Altitude Simulation:

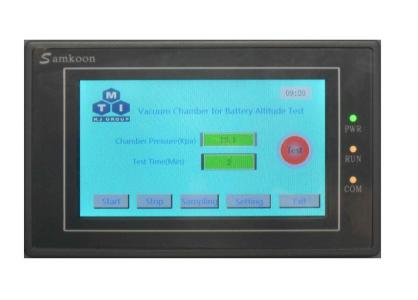

MSK-VA53 Vacuum Chamber for Battery Altitude Simulation (53L) has a larger vacuum chamber with a capacity of 53 liters, a built-in vacuum pump and control system, and is designed for battery altitude simulation tests based on UN38.3 standard (38.3.4.1 UN Altitude Simulation Basic Requirements: This test simulates air transport under low pressure conditions. Test cells and batteries must be stored at a pressure equal to or lower than 11.6 kPa and ambient temperature (20±5℃) for at least 6 hours. If there is no weight loss, no leakage, no exhaust, no disassembly, no rupture and no combustion, and the open circuit voltage of each test cell or battery after the test is not less than 90% of its voltage before this test. The cells and batteries meet this requirement. The voltage requirements do not apply to test cells and batteries in a fully discharged state.), can also be used as an automatic vacuum storage chamber to control the vacuum pressure without vacuum leakage.

Advantages of Vacuum Chamber for Battery Altitude Simulation:

1. Battery height simulation vacuum box can accurately simulate the atmospheric pressure in high altitude areas, and all electrical components (>24V) are UL / MET / CSA certified.

2. Battery height simulation vacuum box adopts advanced pressure control system, which can keep the pressure in the chamber at 11.6KPa to maintain the accuracy of the experiment.

Technical parameters of Battery height simulation vacuum box:

| Product Name | Explosion-proof Vacuum Storage Box (53L) |

| Product Model | MSK-VA53 |

| Technical Parameters | 1. Chamber Material: 304 Stainless Steel and Explosion-proof Tempered Glass. 2. Working Temperature: Room Temperature. 3. Vacuum Degree: < 1000Kpa (7.5 Torr) (A vacuum pump is installed in the instrument) 4. Pressure Control System: The pressure control system can keep the pressure in the chamber at 11.6KPa. 6" touch screen, PLC control, automatic pressure and time control.

5. Vacuum pump: A dual-rotation mechanical pump is installed in the instrument, with a pumping speed of 226L/m.

6. Input power: 110V/220VAC, 50/60Hz. 7. Quality certification: CE certification. All electrical components (>24V) are UL / MET / CSA certified.

|

| Product specifications | Cavity size: 415 mm x 345 mm x 370 mm (16.3 x 13.5 x 14.5) External dimensions: 710 x 560 x 550 mm (28 x 22 x 22") Volume: 53L |

| Warranty | One-year warranty, lifetime maintenance |

About us:

We have advanced production equipment and strict quality management system, so that every product meets international standards. Our R & D team continues to innovate and is committed to improving product design based on market demand and customer feedback to provide more accurate and efficient solutions. With years of industry experience and technical accumulation, we have established a good reputation in the industry and won favorable comments from many customers.