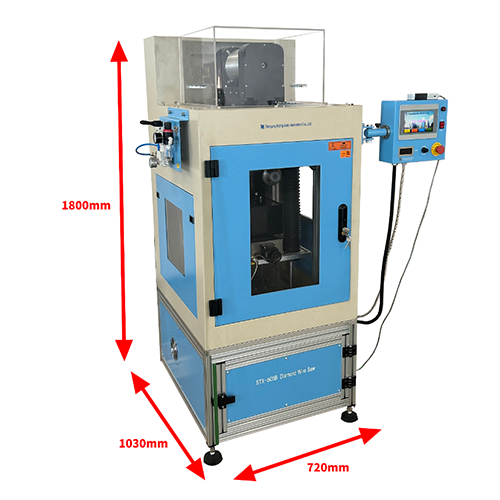

Diamond Wire Saw For Cutting Max. 150mm Diameter

1. Precision Vertical Diamond Wire Saw is suitable for precision cutting of brittle and easy-to-cleave crystals.

2. Precision Vertical Diamond Wire Saw uses diamond wire for cutting, and the cutting quality is excellent.

3. Precision Vertical Diamond Wire Saw adopts aluminum profile structure, which is beautiful and lightweight.

- Shenyang Kejing

- Shenyang, China

- 50 sets

- Information

Key Features Of Precision Vertical Diamond Wire Saw:

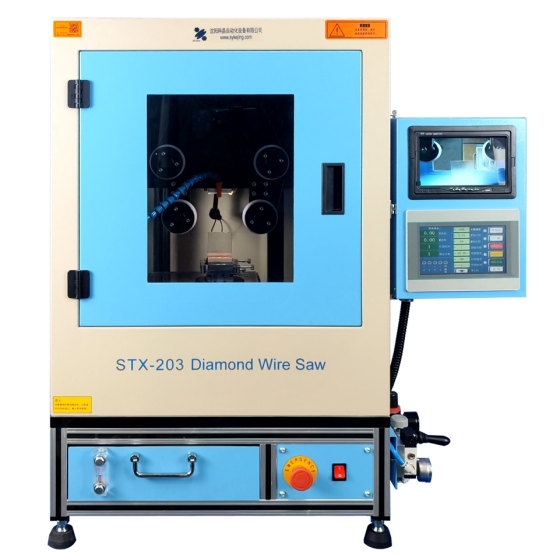

1. STX-605B Precision vertical diamond wire saw is a CE-certified cutting equipment.

2. Diamond wire band saw is mainly used for precision cutting of material analysis samples.

3. The diamond wire band saw is especially suitable for precision cutting of ultra-thin slices, and the thickness of the slices can reach 0.2mm.

4. STX-605B Diamond wire band saw is a continuous cutting diamond wire band saw. After setting the cutting program, the sample is continuously fed without manual adjustment. The dimensional accuracy of the cut sample is high.

4. The cutting wire of the STX-605B diamond wire band saw adopts a single wire reciprocating motion mode. The length of the diamond wire that can be used is (80m or 150m, determined according to the specific equipment model).

5. When the diamond wire band saw is used with the electric turntable, it can perform precise cutting. The surface of the cut sample is in good condition and has a frosted surface without marks.

Diamond Wire Band Saw Technical Parameters:

Product Name | STX-605B diamond wire saw | |

Product Model | STX-605B | |

Diamond Wire Saw Mounting Conditions | 1.Temperature and humidity: 10–85% RH (at 25℃, non-condensing); Temperature: 0–45℃. 2.The equipment must be installed in an environment free from strong vibration sources and corrosive gases. 3.Power supply: Single-phase AC220V, 50Hz, three-pin socket, 10A, with reliable grounding. 4.Air source (compressed air): ≥0.6 MPa. 5.Cooling liquid: Required (cutting oil recommended). 6.Workbench: Not required. 7.Ventilation: No special requirements. | |

Diamond Wire Saw Major Parameters (Specification) | 1.Power supply interface:three-pin socket, AC220V 50Hz 10A 2.Total power:370W 3.Main structure:Aluminum alloy frame with sheet-metal box housing 4.Total length of cutting wire:150m 5.Diameter of diamond wire:φ0.25mm-φ0.45mm 6.Tensioning mode of diamond wire: Adjustable pneumatic tensioning 7.Tension adjustment range: 0.1-0.4MPa 8.Spindle cutting rotation mode: Reciprocating rotation 9.Spindle drive motor: AC variable frequency + reducer, AC220V 300W 10.Spindle speed (linear speed): 0~8 m/s, adjustable 11.Cutting speed: 0.05–30 mm/min 12.Return speed: 1–30 mm/min 13.Z-axis traveling distance: ≤160mm 14. Y-axis traveling distance: ≤180mm 15.Z and Y axis feed accuracy: 0.01 mm 16.Rotary table: Electric, horizontal 0–360° 17.Tilting table: Electric, ±10° 18.Y, Z, and R axis drive motors: Precision stepper motors 19.Maximum spacing between inner sides of the two guide wheels: ≤180 mm 20.Maximum workpiece cutting diameter and length: Φ150 mm × 150 mm 21.Worktable center load capacity: ≤5 kg 22.Control mode: PLC controller + 7-inch touch screen 23.Parameter display: Digital 24.Remote control handle (for alignment): Wired remote handle 25.Safety devices: Spool over-travel protection, automatic stop upon wire breakage, emergency stop switch | |

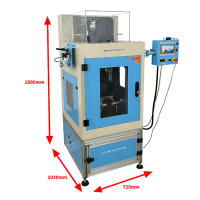

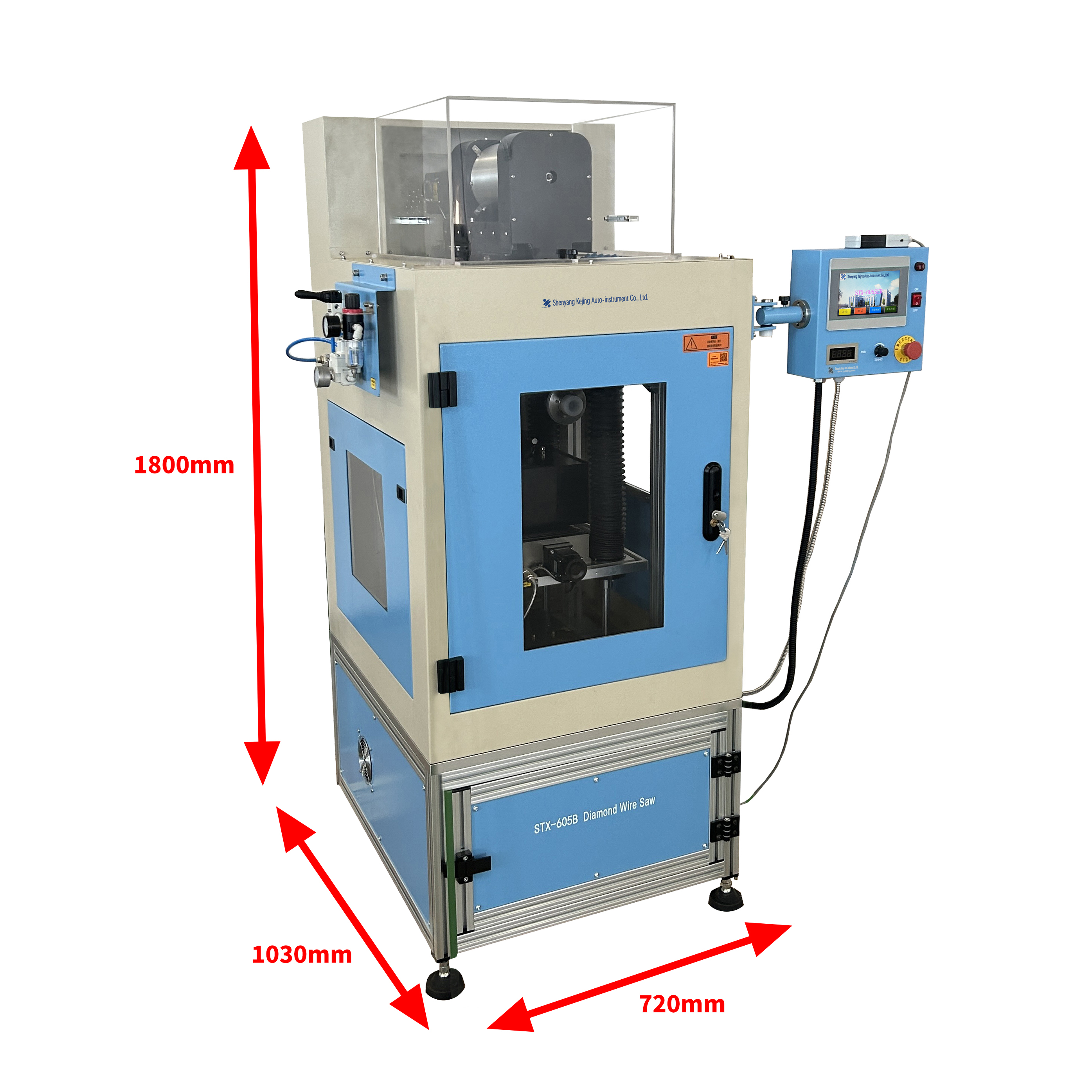

Diamond Wire Saw Dimension and Weight | Dimension:720mm×1030mm×1800mm; Weight:about 310kg |

|

Diamond Wire Saw Functions & Applications | 1. Ceramic materials: alumina ceramics, zinc oxide ceramics, zirconia ceramics, target ceramics,Honeycomb ceramics, semiconductor ceramics, conductive ceramics, non-conductive ceramics, etc.; 2. Crystal materials: graphite, silicon crystal (solar polysilicon, monocrystalline silicon), sapphire,Alumina crystal, infrared glass crystal, alumina crystal, silicon carbide crystal, cesium iodide crystal, etc.; 3. Glass materials: chalcogenide glass, optical glass, quartz glass, infrared glass, glass tube, etc.; 4. Metal materials: iron, aluminum, copper, titanium alloy, magnesium alloy and other metals and alloys, non-ferrous metals (zinc sulfide, ferrite), etc.; 5. Composite materials: PVC boards, carbon fiber composite materials, glass fiber composite materials, etc. 6. Rock materials: precision cutting of natural rocks, jade, meteorites, pei cui, agate, etc.;Precision slicing of various high-value materials; geological light slices, geological thin sections (sedimentary rocks, magmatic rocks, metamorphic rocks, ores), etc. 7. Thermoelectric materials: bismuth telluride, lead telluride, silicon germanium alloy, etc. 8. Infrared optical materials: zinc selenide, zinc sulfide, silicon, germanium and other crystals 9. Biomedical materials: bioplastinated specimen slices(Combined sectioning of human animal organs, soft and hard tissues of the jaw, observation of implants, dental crowns and bridges, teeth and other histological specimens);Combined sections of orthopedic soft and hard tissues (living and hard tissues such as femur, hip joint, vertebral body, etc., bone histology samples with implants, etc.);Cardiovascular and cerebrovascular stent sections, stone sections and other medical tissue sections;

Note: Precision cutting can be performed on any material with a hardness less than that of diamond wire. | |

Diamond Wire Band Saw Standard Accessories:

S/N | Name | Qty | Picture |

1 | PE tension wheel | 2 pcs |

|

2 | PE leading wheel | 2 pcs |

|

3 | Diamond wire | 2 rolls |

|

4 | Water pump | 1 pcs |

|

5 | resin bonded ceramics | 2 pcs |

|

6 | Wax bar | 4 pcs |  |

Diamond Wire Band Saw Optional Accessories:

S/N | Name | Functional Type | Picture |

1 | diamond wire (Ø0.25mm、Ø0.35mm、Ø0.42mm) | (optional) | |

2 | cutting oil | (optional) | |

| 3 | mute oilless air compressor | (optional) | |

4 | DX-100 single crystal direction-finder | (optional) | |

5 | STX-2500 electric wire installer | (optional) |  |

Diamond Wire Saw Warranty;

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Quality Promise:

Our company guarantees that the equipment provided is brand new, unused, and fully meets the quality, specifications and performance requirements stipulated in the contract. Ensure that its equipment should have satisfactory performance under correct installation, correct use and maintenance conditions and within its service life. During the twelve-month quality guarantee period after the final acceptance of the goods, our company is responsible for failures due to defects in design or materials.