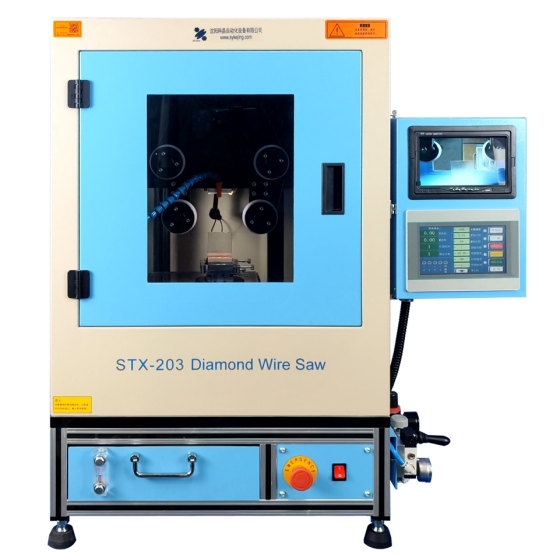

Diamond Wire Cutting Machine

1. The Precision Wire Saw with Sample Stage supports high-precision cutting of ultra-thin samples as thin as 0.2 mm.

2. The Precision Wire Saw with Sample Stage can cut up to 150 meters, improving efficiency and reducing the need for frequent changes.

3. Our Precision Wire Saw with Sample Stage features a continuous cutting mode for automatic operation while ensuring sample accuracy.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of the High Precision Diamond Wire Saw Machine:

The STX-630B High Precision Diamond Wire Saw Machine is a CE-certified, high-precision cutting machine designed for precision cutting of material analysis samples. It is suitable for a wide range of applications, including ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials, and biomedical materials. The High Precision Diamond Wire Saw Machine is particularly suitable for preparing ultra-thin samples, with thicknesses as thin as 0.2 mm.

The STX-630B High Precision Diamond Wire Saw Machine is a continuous-cutting diamond wire saw. Users simply set the cutting program, and the sample is automatically fed continuously, eliminating the need for manual adjustment. This ensures dimensional accuracy and stability of the cut sample. The High Precision Diamond Wire Saw Machine's cutting system utilizes a single diamond wire in a reciprocating motion, allowing for a maximum wire length of 150 meters. This long wire life significantly improves cutting efficiency.

The High Precision Diamond Wire Saw Machine is equipped with a pneumatic tensioner, allowing for flexible adjustment of tension based on the wire diameter, effectively preventing wire breakage due to over-tensioning. When used with a motorized turntable, the Laboratory Precision Cutting Machine achieves high-precision cutting, resulting in smooth, flat, and frosted surfaces with no noticeable wire marks.

Key Features of the Laboratory Precision Cutting Machine:

· The Laboratory Precision Cutting Machine is suitable for precision cutting of brittle, easily dissociated crystals.

· The Laboratory Precision Cutting Machine uses diamond wire for cutting, resulting in excellent cut quality.

· The Laboratory Precision Cutting Machine utilizes an aluminum extrusion structure, making it aesthetically pleasing and lightweight.

Technical Parameters of the Laboratory Precision Cutting Machine:

| Product Name | STX-630B Diamond Wire Cutting Machine | |

| Model | STX-630B | |

| Installation Requirements | 1. Temperature and Humidity Requirements: Relative Humidity 10–85% RH (25°C, non-condensing), Ambient Temperature 0–45°C. 2. Operating Environment: No strong vibration sources or corrosive gases. 3. Power Supply Requirements: Single-phase AC 220V, 50Hz, 10A, national standard three-pole socket, ensure reliable grounding. 4. Air Source Requirements: Compressed air ≥ 0.6 MPa. 5. Coolant: Required (cutting oil recommended). 6. Workbench: No special requirements. 7. Ventilation: No special requirements. | |

| Function and Application | 1. Ceramic Materials: Alumina ceramics, zinc oxide ceramics, zirconium oxide ceramics, target ceramics, honeycomb ceramics, semiconductor ceramics, conductive ceramics, non-conductive ceramics, etc. 2. Crystal Materials: Graphite, silicon crystals (solar polycrystalline silicon, single crystal silicon), sapphire, alumina crystals, infrared glass crystals, silicon carbide crystals, cesium iodide crystals, etc. 3. Glass Materials: Chalcogenide glass, optical glass, quartz glass, infrared glass, glass tubes, etc. 4. Metal Materials: Iron, aluminum, copper, titanium alloys, magnesium alloys and other metals and alloys, non-ferrous metals (zinc sulfide, ferrite), etc. 5. Composite Materials: PVC boards, carbon fiber composites, glass fiber composites, etc. 6. Rock Materials: Precision cutting of natural rocks, jade, meteorites, pejay, agate, etc.; precision sectioning of various high-value materials; and slicing of geological sections and thin sections (sedimentary rocks, igneous rocks, metamorphic rocks, ores). 7. Thermoelectric Materials: Bismuth telluride, Lead Telluride, Silicon-Ge Alloy, etc. 8. Infrared Optical Materials: Crystals of Zinc Selenide, Zinc Sulfide, Silicon, Germanium, etc. 9. Biomedical Materials: Plastinated Specimens (Human and Animal Organs, Mandibular Soft and Hard Tissue Sections, Implant Observation, Dental Crowns and Bridges, Dental Histological Specimens, etc.); Orthopedic Soft and Hard Tissue Sections (Fresh and Hard Tissue of Femur, Hip Joint, Vertebral Body, etc., Bone Histological Specimens with Implants, etc.); Cardiovascular Stent Sections, Stone Sections, and Other Medical Tissue Sections; Note: Any material with a hardness lower than that of diamond wire can be precision cut. | |

| Main Parameters of Precision Wire Saw with Sample Stage | 1. Power Supply: National standard three-pole socket with fuse, AC220V, 50Hz, 10A 2. Total Power: 620W 3. Main Structure: Aluminum alloy frame + sheet metal box housing 4. Diamond Wire Length: ≤150m 5. Diamond Wire Diameter: φ0.25–0.45mm 6. Diamond Wire Tensioning: Pneumatic, adjustable 7. Tensioning Pressure Range: 0.1–0.4MPa 8. Spindle Cutting Motion: Reciprocating 9. Spindle Drive Motor: AC variable frequency motor, AC220V, 370W 10. Spindle Speed: 0–15m/s, adjustable 11. Cutting Feed Speed: 0.05–40mm/min 12. Retract Speed: 1–100mm/min 13. Z-Axis Effective Travel: ≤160mm 14. Y-Axis Effective Travel: ≤180mm 15. Z/Y-axis feed accuracy: 0.01mm 16. Horizontal rotation stage: Electric, 0–360° 17. Tilt stage: Electric, ±10° 18. Drive motor: Precision stepper motor (Y, Z, and R axes) 19. Maximum guide wheel spacing (inside): ≤180mm 20. Maximum workpiece size: φ150mm × 150mm 21. Center load capacity of worktable: ≤5kg 22. Control: PLC controller + 7-inch touch screen 23. Parameter display: Digital display 24. Tool setting device: Wired remote control 25. Safety features: Winding bobbin overtravel protection, automatic shutdown due to wire breakage, emergency stop switch | |

26. Product Specifications: Dimensions: 780mm × 830mm × 1680mm Weight: ≈275kg |  | |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. | |

Standard accessories for Precision Wire Saw with Sample Stage:

| NO. | Name | Quantity | Image Link |

| 1 | Tensioner pulley | 2 pcs |  |

| 2 | Guide pulley | 2 pcs |  |

| 3 | Diamond wire | 2 rolls |  |

| 4 | Water pump | 1 pc |  |

| 5 | Resin ceramic block | 2 blocks |  |

| 6 | Paraffin wax stick | 4 sticks |  |

Optional Accessories of Precision Wire Saw with Sample Stage:

About us:

We are not only an equipment supplier, but also a provider of scientific research services. We serve the society with innovative technology, always put customers' needs first, and are committed to providing customers with the best solutions. We pursue excellence and strive to become a well-known brand of domestic materials analysis instruments and win respect and trust in the international market. When you choose Shenyang Kejing, you will choose a dynamic and progressive partner.