1700℃ High Temperature Box Furnace (125L)KSL-1700X-A5

1. 125L ultra-large capacity, 1700℃ maximum temperature: Large capacity and high temperature to meet the extreme sintering requirements of large-sized or batch samples.

2. ±1℃ ultra-precise temperature control, double protection to prevent sample damage: 50-segment intelligent program combined with a "dual controller" design.

3. Imported heat-reflective coating, fast heating and cool-to-the-touch exterior: Uses an imported American inner chamber coating for high thermal efficiency and features double-layer air cooling for extremely safe operation.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction to the High Temperature Box Furnace:

The KSL-1700X-A5 High temperature box furnace is a CE-certified high-temperature sintering furnace that integrates the control system and the furnace chamber. High-temperature muffle furnace uses silicon molybdenum rods as heating elements, and is equipped with an 858P intelligent temperature controller and a type B platinum-rhodium thermocouple for temperature measurement, regulation, and automatic control of the furnace chamber. The furnace door and door plug are integrated for easy sample loading and unloading. The maximum furnace temperature is 1700℃. This is a suitable device specially designed for sintering, melting, and analysis of metals, non-metals, and their compounds in laboratories of universities, research institutes, and industrial and mining enterprises.

Main Features of the Large High Temperature Box Furnace:

1. The internal volume of the equipment can reach 125L, suitable for sintering larger materials.

2. The maximum temperature of the equipment can reach 1700℃.

3. The furnace door and door plug adopt an integrated design, making it convenient to load and unload samples.

4. Double-layer shell structure with an air cooling system ensures that the surface temperature of the shell does not become excessively high.

5. Power is automatically cut off when the door is opened, ensuring safe operation.

Technical Parameters of High Temperature Lab Furnace:

Product Name | KSL-1700X-A5 High temperature box furnace |

Product Model | KSL-1700X-A5 |

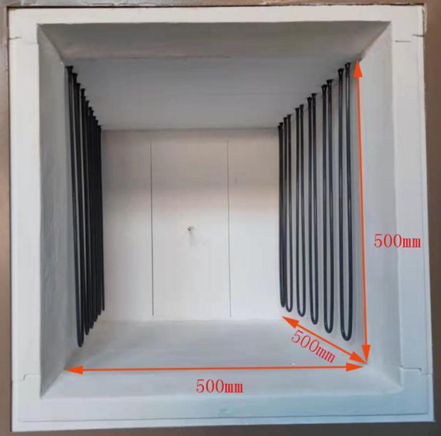

Technical Parameters | • Working temperature: 1600℃ (continuous), 1650℃ (<0.5h) • Heating rate: 10℃/min (≦1400℃), 5℃/min (1400℃-1600℃), 2℃/min (>1600℃) • Heating element: Silicon molybdenum rod • Thermocouple: Type B double platinum-rhodium thermocouple • Voltage: AC380V three-phase, 50/60Hz • Maximum power: 32KW Note: Lower heating rates extend the lifespan of the heating elements. • Furnace chamber dimensions: 500 × 500 × 500 mm (usable internal dimensions of the furnace chamber)

|

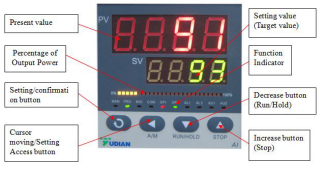

Temperature Control System | • Includes a YD858P temperature controller (an optional Eurotherm controller with a temperature accuracy of ±0.1℃ is also available) • PID automatic temperature control system • Intelligent 50-segment programmable control • Temperature control accuracy: ±1℃ • Default DB9 PC communication port • All components are UL or MET approved and can pass other relevant safety tests worldwide.  |

Furnace Structure | • The inner furnace chamber surface is coated with imported American high-temperature alumina coating to improve reflectivity and heating efficiency, while also extending the instrument's service life. • The universal digital power controller operates at a frequency of 50-60Hz, making it suitable for use worldwide. • It features overheating and thermocouple failure protection, as well as an automatic power cut-off function when the door is opened. |

Main Controller and Detectors | • The main controller and thermocouple allow for user-defined heating programs and are equipped with a primary alarm system. • The monitoring controller only monitors the actual temperature of other thermocouples and activates a secondary alarm system in case of main controller failure to ensure safety.  |

Inlet and Outlet Ports | • The pagoda-shaped air inlet is installed at the back of the furnace body, and the air outlet is installed at the top of the furnace. |

Product Specifications | • Furnace dimensions: L 1000 × W 1040 × H 1800 mm • Net weight: 520 kg |

| Certifications | • CE certified • If the customer covers the certification costs, our company guarantees that each unit will pass German TUV or CAS certification. |

Warranty Period:

One-year warranty, lifetime maintenance (excluding the furnace chamber and heating elements)

About Us:

Kejing was founded in 2000 and is a national high-tech enterprise integrating R&D, manufacturing, and sales. We specialize in providing precision instruments and systematic solutions covering the entire material preparation process for research institutions, universities, and factories worldwide.

Core Strengths:

1. 25 Years of Industry Experience: Since the launch of the first SYJ-150 low-speed diamond cutting machine in 2000, we have been deeply rooted in the field of material analysis equipment for over 25 years.

2. Modern Base: The company owns an independent R&D and manufacturing center covering an area of 12500 square meters.

3. Hundreds of Product Matrix: Our products cover 8 major fields, including cutting, grinding, polishing, coating, mixing, rolling, sintering, and analysis, with hundreds of models and supporting consumables, providing "one-stop" experimental solutions.

4. 20% R&D Staff Ratio: Among our more than 100 employees, the core technical team accounts for over 20%, with several experts possessing top international backgrounds from institutions such as MIT.

5. 100% Core Product International Certification: Our three major product series—cutting, grinding and polishing, and coating—have all passed CE certification, and production management strictly adheres to ISO 9001 quality system standards.

6. Top-Tier Research Coverage: Our products are widely used in top universities such as Tsinghua University and Peking University, as well as national key laboratories, and we provide in-depth services to leading state-owned enterprises such as AVIC, China Electronics, and China Shipbuilding.

Technological Advantages and Market Performance:

1. We have accumulated and applied for dozens of invention patents and utility model patents, filling several gaps in domestic diamond wire cutting and ultra-high-pressure precision sample preparation technologies.

2. We actively participate in international academic conferences such as ICPNS (Russia) and PRICM (Pacific Rim International Conference on Advanced Materials), with our services reaching multiple countries and regions worldwide.

3. Relying on our experienced sample preparation technology team, we not only provide equipment but also mature sample preparation process technologies.