Working Principle of Diamond Band Saw

2022-07-13 10:04Working Principle of Diamond Band Saw:

The diamond band saw uses a motor to drive the driving wheel, and with the motion of the driving wheel, the band blade is transmitted to the driven wheel, so that the band blade rotates rapidly in a one-way cycle, and the material to be cut performs a reciprocating linear motion to achieve a cut. In order to keep the running track of the band blade accurate and stable and that the band blade will not move left and right, guide baffles are used on both sides of the band blade above and below the sample holding stage. Coolant or cooling water is used onto the sample and the cutting part of the band blade to ensure a certain stability during the cutting process of the band blade[1]. The characteristic of the diamond band saw’s processing method is that samples of different specifications can be cut according to the specifications of the band saw.

Advantages of diamond band cutting:

Annular diamond band saw blade refers to a type of diamond tool made by using a unique electro-deposition technique to consolidate diamond particles on the deposited layer through the electro-crystallization of metal on a preferred annular band substrate. Diamond is the most advanced superhard material in the world. It is a tool for straight and curved cutting of brittle materials. It has a wide range of cutting materials and can be used to cut any non-metallic, superhard and highly brittle materials (such as marble, agate, hard alloys, glass, magnetic alloys). It has four major advantages: saving energy and raw material; good cutting quality (flat and smooth); high cutting efficiency, good forming performance; not easy to brittle.

The speed of cutting carbide, marble and granite is dozens of times that of traditional reciprocating saws or wire saws, and the kerf/incision is narrow (only 1.2mm-2mm), so the material consumption is low, the dust generated is low, and the noise is low. It is especially of great economic significance for precious material cutting. The thickness of diamond band edge (i.e. the working part of the band blade) is greater than that of the substrate steel band. With the help of the guide device, the band blade does not contact the added surface, which is conducive to obtaining a more stable blade seams and higher machining quality [2].

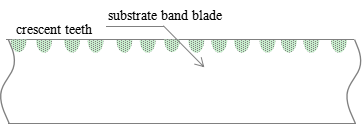

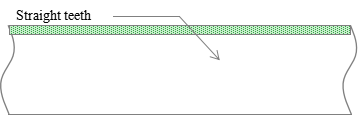

Compared with traditional reciprocating saws and circular saws, it can save a lot of raw materials and bring significant economic efficiency to users. These advantages are unmatched by traditional reciprocating saws and circular saws. At present, the specifications of annular diamond band blades are complete, and the tooth shapes mainly include crescent teeth and straight teeth. The tooth shapes are shown in Figures 1 and 2 below.

Figure 1: crescent-teeth band blade

Figure 2: straight-teeth band blade

Structure diagram of diamond band blade

Selection of diamond band blade

For cutting thin materials (below 6mm), a straight tooth saw blade should be selected; for cutting thick materials (above 6mm), a crescent tooth saw should be selected. A straight-tooth band blade should be used for curved cutting, and a straight-tooth saw should be used for small materials. The thicker the material, the bigger the tooth band blade can be used[3].

What is the range of sizes and types of annular diamond band blade that can be used?

There are two types of diamond band saws produced by SHENYANG KEJING AUTO-INSTRUMENT CO., LTD. The two machines are shown in Figures 3 and 4 below:

Figure 3: SYJ-D2000 manual diamond band saw

SYJ-D2000 diamond band saw is a small diamond band saw, which is mainly used for cutting materials, and the cutting speed is fast. The materials that can be cut are glass, ceramics, jade, marble, concrete and other brittle materials. This machine can perform not only straight line cutting, but also cutting at certain angles and curve cutting, which is an ideal tool cutting brittle materials at laboratories.

Main features: small size, convenient operation and stable operation.

1. Band blade circumference: 945mm

2. Band blade width: <1mm

3. Cutting thickness: <30mm

4. Workbench size: 300mm×250mm

Figure 4: SYJ-D4000 diamond band saw

SYJ-D4000 diamond band saw is a medium-sized diamond band saw. According to different specifications and sizes, the sample fixture has its own characteristics and is stable and easy to operate. The workbench feeding system has the advantages of precise guidance, stable operation, and convenient adjustment, and can realize program control. The cutting speed is fast, the cutting surface is flat, and it is suitable for the cutting of samples with a certain height.

1. Saw blade linear speed: >600m/min

2. Manual minimum cutting radius (not including band blade): 10mm

3. Automatic cutting diameter of bar material: φ60mm

4. Normal kerf/incision width: <1.2mm

5. Manual maximum cutting thickness: 100mm

6. Automatic cutting distance: >100mm

7. Maximum cutting span: 320mm

8. Dimension: 700×1220×1260mm

References:

1. Application of diamond band saw cutting technology in ultra-thin stone slab cutting [J]. Fujian Building Materials, 2001(2):40-41.

2. Chen Guangran. Application of diamond band saw cutting technology [J]. High Voltage Electrical Appliances, 1987(3):50-51.

3. Experimental research on annular diamond band blades (Part 1). CNKI. 2012-08-15 [reference date 2014-12-25]