- Home

- >

- News

- >

- Industry News

- >

News

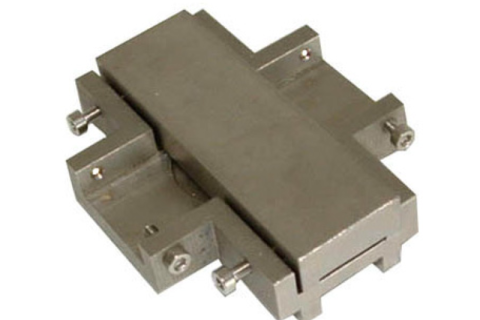

Designed to meet the precision cutting needs of professionals, our precision mechanical rotary platform provides precise control and accuracy during the cutting process. Let's take a look at its performance!

In modern material analysis and processing, precision cutting is a key link to ensure experimental success and product quality. Our STX-100QX precision universal machine is designed to meet the needs of high-precision cutting.

Against the background of continuous upgrading of the global manufacturing industry, the industrial vertical band saw is ushering in a new technological revolution. The diamond band saw cutting machine launched by our company adopts advanced intelligent control system and advanced manufacturing technology to make the cutting process more accurate and efficient. Through automatic cutting, users can significantly improve production efficiency and reduce material waste.

Against the background of continuous upgrading of the global manufacturing industry, the industrial vertical band saw is ushering in a new technological revolution. The diamond band saw cutting machine launched by our company adopts advanced intelligent control system and advanced manufacturing technology to make the cutting process more accurate and efficient. Through automatic cutting, users can significantly improve production efficiency and reduce material waste.

In today's context where the world is paying more and more attention to energy conservation and emission reduction, our company has launched a low-speed metallographic sample cutting machine with its innovative technological strength.

In engineering construction projects, diamond band saw are widely used in cutting and processing of various materials. However, since improper operation of the cutting machine may pose a threat to the safety of construction workers, it is necessary to master the safe operation skills of the cutting machine.

Laboratory cutting is inseparable from precision cutting technology, and the precision dicing saw with 8 inches round and205mm square workbench can perform precision cutting very well. This cutting machine is equipped with an 8-inch round disc and a 205mm square workbench. It is not only easy to operate, but also marks an important breakthrough in our precision machining field, providing a new solution for various industries.

Our company has launched the new diamond band saw for cutting max, 200mm T, which is designed for applications with a maximum cutting thickness of 100mm, providing an excellent cutting solution for the field of scientific research. As a high-performance cutting machine, the dlamond band saw for stone is an ideal choice for scientific laboratories and research institutions.

In order to ensure the long-term stable operation and optimal performance of the precision cutting saw, we have some precautions and maintenance methods when using it. Let's learn about it together!

With the continuous innovation and research and development of our company, we have launched the precision dicing saw with 6 inches round and 160mm square workbench. This dicing machine is famous for its high precision, high efficiency and versatility, and has become a popular choice for geology, mining, metallurgy, aerospace, and automobiles. It is an indispensable and important equipment in many fields.

The cutting machine is a device specially used for cutting thin slices or samples. It is suitable for cutting thin single crystal substrates. The cutting pressure can be adjusted by springs. The cutting stroke is 100mm. The operation is relatively simple but requires certain skills and precautions. Let us fully understand how to use it!