Vacuumable And Atmospher Controlled Spin Coater

VTC-200PV Vacuum Spin Coater is suitable for semiconductor process, crystal, optical disc, plate making and surface coating, etc. The chamber of VTC-200PV vacuum spin coater can be vacuumized to coat the sample under completely vacuum condition, which is suitable for film materials that are easily oxidized and deteriorated in air. A clamp is used to fix the sample when the chamber is vacuumized. The equipment can store 12 sets of programs, and each set contains 6 running stages.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction

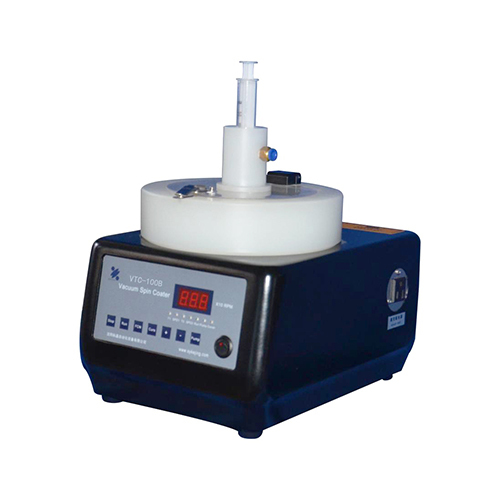

The VTC-200PV Vacuum Spin Coater is designed for surface coating processes in semiconductors, crystals, optical discs, lithography, and related applications. It is suitable for preparing coatings with strong acid or strong alkaline solutions.

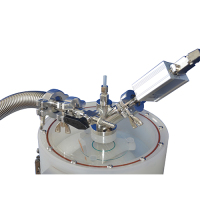

This system can evacuate the coating chamber, allowing samples to be coated under a complete vacuum. This feature is particularly suitable for thin-film materials that are prone to oxidation or degradation in air. During vacuum operation, samples are fixed using a sample chuck.

When not using vacuum evacuation, samples are held on the substrate holder via vacuum adsorption. The system can store up to 12 programs, each containing 6 sequential stages. Different rotation speeds can be set for each stage, allowing the coater to gradually accelerate to its maximum speed. This ensures uniform thin film formation on the sample surface while minimizing material waste.

With advantages such as easy operation, convenient cleaning, and compact design, the VTC-200PV Vacuum Spin Coater is widely used in laboratories of universities and research institutes for thin-film preparation.

Main Features

1. The equipment can store 12 sets of programs, and each set contains 6 running stages. The setting range of the acceleration and deceleration rate for each stage: 100rpm/s-2000rpm/s, time range for each stage: 0-60s

2. The sample is fixed by means of vacuum adsorption and it can also be fixed by means of bonding or clamping, which is easy to operate.

3. The degree of vacuum can reach -0.08MPa.

4. Samples can be easily centered using the positioning tool to reduce vibration or fly-outs caused by misalignment.

5. Different chucks can be used according to sample specifications, and the replacement is convenient and simple.

6. A 24V brushless DC motor is adopted and it has the advantages of high reliability, strong adaptability, simple repair and maintenance, low noise, small vibration, stable operation, fast and stable startup, stable operation after acceleration, to ensure the consistency and uniformity of coating thickness.

7. The oilless parallel-bar vacuum pump is used when the sample is fixed by means of vacuum absorption, and it has the advantages of small size, simple structure, easy operation, convenient maintenance, and no environmental pollution.

8. Coating can be carried out in an inert gas atmosphere (such as Ar, N2).

9. When coating is performed under vacuum condition, the sample substrate is fixed by means of bonding or clamping.

10. The chamber is made of PP material with longer service life to improve the resistance abilities of chemical corrosion and excellent stress crack, and the machine body adopts cast aluminum structure, which is durable and light in weight.

11. English operating system

12. It has the function of open-cover protection. When the top cover is opened during the coating process or at the end of the coating, the machine immediately decelerates rapidly until it stops.

13. The controller adopts a control box with LCD numerical display, which is more intuitive and reliable.

Technical Parameters

Product Name | VTC-200PV Vacuum Spin Coater |

Product Model | VTC-200PV |

Installation Conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong earthquake source and corrosive gas around the equipment. 3. Water: The equipment is equipped with a sewage outlet 4. Electricity: Single phase: AC220V 50Hz 10A . 5. Gas: Vacuum negative pressure (vacuum pump) exhaust flow rate is not less than 70L/min (the equipment can pass protective inert gas) 6. Workbench: It is recommended to be 1500mm×600mm×700mm and bear a load of more than 100kg (solid cement platform is better) 7. Ventilation device: No special requirements |

Main Parameters (Specification) | 1. Power Supply Interface: Fused power socket: AC220V, 50Hz; Fuse specification: 10A, φ5×20mm. 2. Total Power: ≤600W (including 450W linked oil-free vacuum pump). 3. Main Chamber (Material): Polypropylene. 4. Substrate Holder (Chuck + Vacuum Chuck): Standard configuration: 1 chuck-type substrate holder (adaptable for 2″, 3″, 4″ samples) and 1 Ø100 mm polypropylene vacuum chuck. 5. Operation Mode: Stores up to 12 programs, each containing 6 sequential stages. 6. Spin Speed: 500–6000 rpm (effective). 7. Acceleration/Deceleration Rate per Stage: Adjustable range: 100–2000 rpm/s. 8. Time per Stage: Adjustable range: 0–60 s. 9. Speed Stability: ±1%. 10. Control System: PCB microcontroller with keypad operation and LMC LCD display. 11. Product Dimensions & Weight: · Main Unit: Ø250 mm × 360 mm · Control Box: 330 mm × 380 mm × 150 mm · Weight: 25 kg 12. Supporting Equipment: · Model: AP-1400C/V, powered via main unit linked socket · Voltage: AC220V, 50/60Hz, 2A, 0.45 kW · Ultimate Vacuum: –0.0933 MPa · Pumping Speed: 150 L/min · Mechanical Vacuum Pump (for coating chamber evacuation) · Model: VRD-8, powered via independent socket · Voltage: AC220V, 50Hz, 2.5A, 0.4 kW · Ultimate Vacuum: 5×10⁻² Pa · Pumping Speed: 8 m³/h |

Standard Accessories

No. | name | qty | picture |

1 | Vacuum Chuck (φ100mm) | 1 pcs | |

2 | Clamping Plate 2”, 3”, 4” | 1 pcs | |

3 | Central Positioner/Locator (including 4 positioning studs) | 1 pcs | |

4 | Epoxy Injector/Syringe | 1 pcs |

|

5 | Oilless Vacuum Pump | 1 pcs | |

6 | Double-Click Rotary Vane Vacuum Pump VRD-8 | 1 pcs |

Optional Accessories

No. | name | functional type | picture |

1 | Vacuum Chuck of other specifications | (optional) |

|

2 | Pipette (made in China) | (optional) |

|

3 | Pipette (imported) | (optional) |

|

4 | VRD-16 Mechanical Pump | (optional) |

|

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics