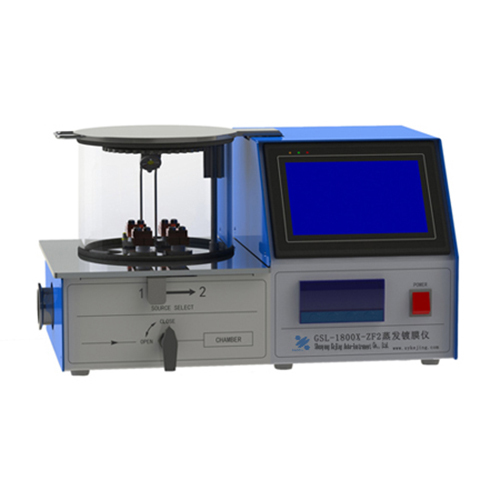

Vacuum Thermal Evaporation Coater With Two Heating Sources

GSL-1800X-ZF2 Evaporation Coater can be rotated during the evaporation coating process, so that the evaporated film material is evenly distributed on sample surface. The machine is equipped with two groups of evaporation units, one W-boat and one tungsten wire basket.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Product Introduction

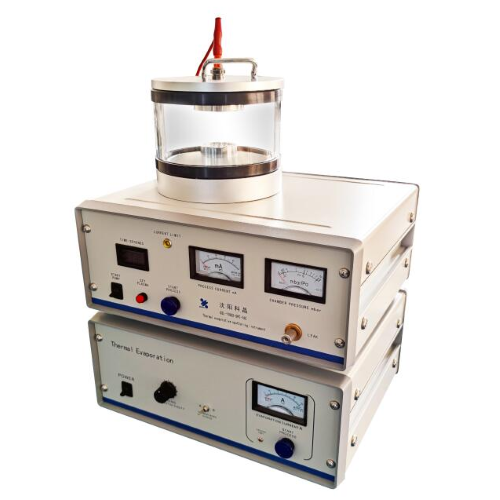

The GSL-1800X-ZF2 Evaporating Coater is a high-performance vacuum evaporation coating system designed for universities, research institutes, and enterprise laboratories. It is suitable for thin film process studies, sample fabrication, operator training, and small-scale production.

This system features a high-vacuum design with an ultimate vacuum of 3.0×10⁻⁴ Torr, ensuring high-purity and uniform film deposition. The rotating sample stage allows the evaporated materials to be evenly distributed across the substrate surface, improving film density and uniformity.

The coater is equipped with two independent evaporation sources — a tungsten boat for powder materials and a tungsten wire basket for strip or pellet materials — to accommodate a wide range of coating applications.

A 7-inch TFT touchscreen serves as the main control interface, providing a graphical, user-friendly layout with high response speed, brightness, and contrast. Users can easily monitor and adjust temperature, time, and vacuum parameters in real time.

With its stable performance and intuitive operation, the GSL-1800X-ZF2 is an ideal evaporation coating system for both research and teaching purposes.

Main Features

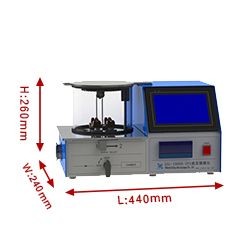

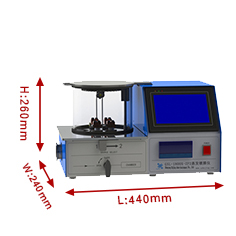

1. It adopts a desktop small integrated structure, to integrate vacuum chamber, coating power supply and control system. The size is similar to that of an A3 printer.

2. It adopts resistance type double evaporation source structure, which can quickly switch evaporation source. The evaporation unit is equipped with two groups of evaporation electrodes, which can be installed with different evaporation sources to adapt to corresponding coating materials.

3. It is equipped with 0.1% precision evaporation power supply, and has a constant current output function, which can well protect the evaporation boats.

4. Optional quartz crystal film thickness controller is available to control the coating rate and film thickness during the coating process.

5. The collected coating data can be saved to the U disk, which is convenient for users to analyze and control (optional).

6. All functions of this machine are designed into standardized modules, and corresponding modules are combined according to users' different needs to achieve an excellent coating environment and facilitate users’ maintenance.

7. The control screen adopts a 7-inch TFT display screen to show the operation interface with touch screen operation and realizes a full graphical interface, easy to use and understand.

Technical Parameters

Product Name | GSL-1800X-ZF2 Evaporation Coater | |

Product Model | GSL-1800X-ZF2 | |

Installation Conditions | This equipment is required to be used at a temperature of 25℃±15℃, and a humidity of 55%Rh±10%Rh. 1. Water: The equipment is equipped with a self-circulating water cooler (filling with pure water or deionized water) 2. Electricity: AC220V 50Hz, must have good grounding 3. Workbench: Floor type, covering an area of more than 2m2 5. Ventilation device: needed | |

Major Parameters (Specification) | 1. Power supply: AC220V 1500W 2. Evaporation supply power: 2500W 3. Effective distance of evaporation electrode: 44mm 4. Sample stage: Ø120mm (rotatable) 5. Film thickness measurement accuracy: 0.1 Å or 0.01 Å (optional high-precision type) 6. External vacuum unit: diffusion pump unit (use of diffusion pump is not recommended) 7. Ultimate vacuum: >8.0×10⁻³ Pa (diffusion pump), 8.0×10⁻⁴ Pa (molecular pump) (use of diffusion pump is not recommended) 8. Working vacuum degree: 5.0×10⁻³Pa 9. Vacuum interface: KF40 10. Application environment: temperature of 35℃, humidity of <75%, non-condensing. | |

11. Product Specifications: · Dimension: 440mm×240mm×260mm (excluding vacuum unit) · Weight: about 47kg (excluding vacuum unit) |

| |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics