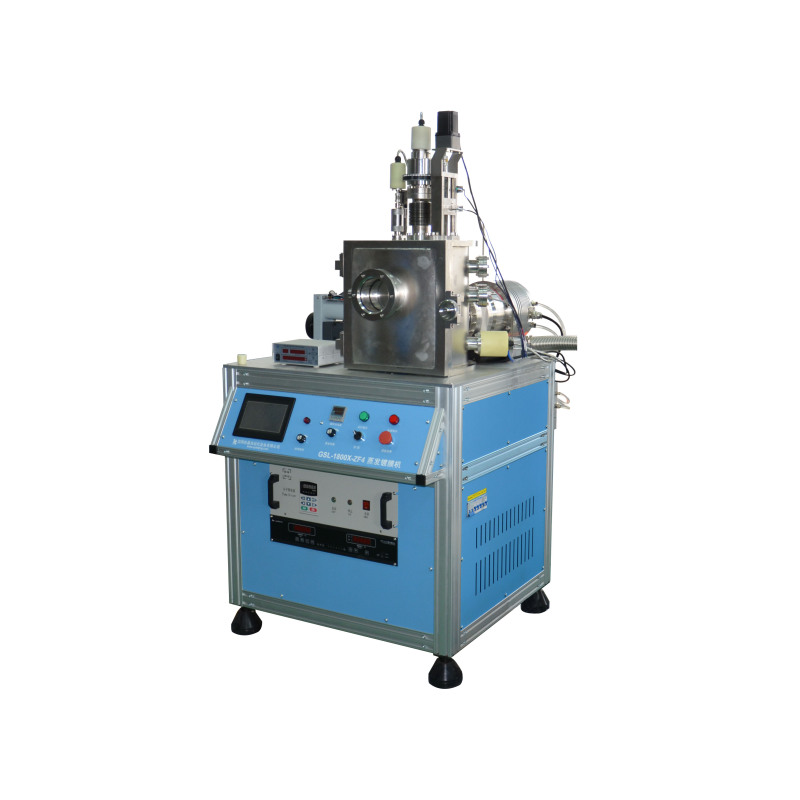

Vacuum Thermal Evaporation Coater With Four Heating Sources

GSL-1800X-ZF4 Evaporation Coater is a high vacuum evaporation coater, especially suitable for evaporation and coating oxygen sensitive metal films (such as Ti, Al, Au, etc.) and small molecular organics. The machine is equipped with 4 evaporation heating boats, each of which can perform evaporation independently.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Product Introduction

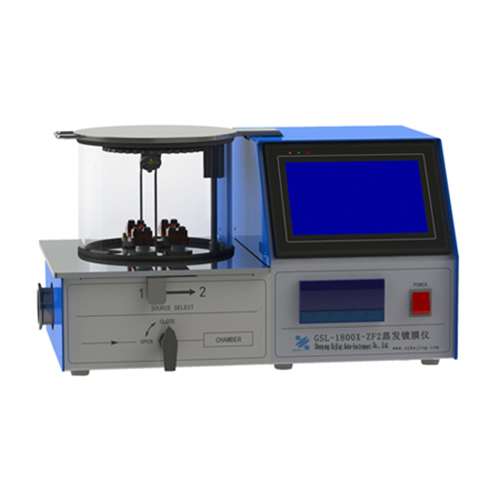

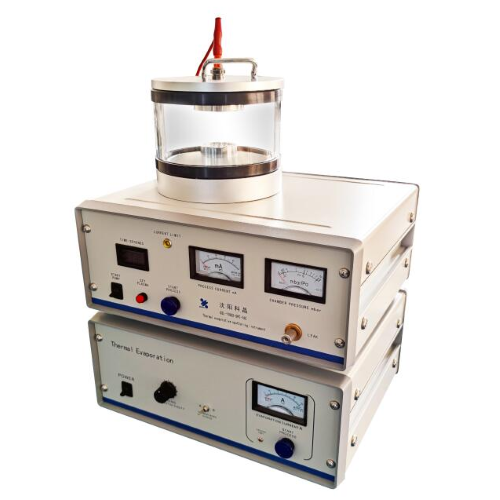

The GSL-1800X-ZF4 Evaporation Coater is a high-vacuum evaporation coating system specially designed for depositing oxygen-sensitive metal films (such as Ti, Al, Au) and small-molecule organic materials. The system is equipped with four independent heating evaporation boats, each capable of operating separately. A rotatable shield above the boats protects the other three boats during evaporation, effectively preventing cross-contamination between materials. With optional configuration adjustments, it can also deposit organic materials, meeting the research needs of light-emitting devices and organic solar cells. This makes it a high-performance and cost-effective laboratory coating system.

The chamber bottom features five water-cooled electrodes to maintain electrode temperature during operation, preventing overheating, melting, or damage. The unit uses a metal vacuum chamber capable of reaching a maximum vacuum of 5.0×10-7 torr. The sample stage is heated from room temperature up to 500°C, making it an ideal choice for high-vacuum evaporation coating experiments.

Main Features

1. The vacuum control units are all assembled in one control box.

2. It adopts an independent evaporation coating current controller, which is convenient and quick to operate.

3. The vacuum chamber is equipped with one KF40 side pumping valve (directly connected to the front-stage mechanical pump to improve efficiency), one CF150 gate valve (directly connected to the molecular pump), one KF16 flange (to install the resistance gauge), six CF35 flanges (one is to install ionization gauge, one is to install 2-core electrode, and one is to install film thickness gauge) and 3 spares.

4. There are 5 water-cooled electrodes at the bottom of the chamber, which can support 4 evaporation heating boats.

5. The sample stage is installed on the top of the chamber.

6. A high-resolution film thickness gauge can be installed in the chamber, and the resolution of film thickness measurement (aluminum) is 0.1Å.

7. A circulating water cooler can be used.

Technical Parameters

Product Name | GSL-1800X-ZF4 Evaporation Coater | |

Product Model | GSL-1800X-ZF4 | |

Installation Conditions | This equipment is required to be used at a temperature of 25℃±15℃, and a humidity of 55%Rh±10%Rh. 1. Water: The equipment is equipped with a self-circulating water cooler (filling with pure water or deionized water) 2. Electricity: AC220V 50Hz, must have good grounding 3. Workbench: Floor type, covering an area of more than 2m2 5. Ventilation device: needed | |

Major Parameters (Specification) | 1. Input: single-phase AC220V, 50Hz/60Hz, power <2.16kW (not including the vacuum pump) 2. Evaporation output: voltage AC 0-8V continuously adjustable, limit evaporation current 200A, limit evaporation power <1.6kW 3. Vacuum chamber: Ø300mm (ID)×360mm(H), stainless steel, electropolished inner wall 4. Observation window: Ø100mm, sealed with special sealing ring 5. Vacuum pump: high pumping speed turbo molecular pump with pumping speed of 600L/s 6. Vacuum degree:8.0×10-4Pa 7. Limit of vacuum :8.0×10-5Pa 8. Leakage rate: 6.7×10-8Pa·L/s 9. Sample stage: φ120 10. Distance between evaporation boat and sample stage: 140-200mm 11. Cooling water required: 15L/min 12. Heating temperature of sample stage: room temperature ~ 500 ℃, automatic temperature control and temperature measurement | |

Product Dimension and Weight | 13. Product Specifications: · Dimension: 900mm×1100mm×1800mm · Weight: 230kg |

|

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics