SP-MSM Series Multi-Station Suction Casting Melting Furnace

1.Multi-Station Automatic Arc Melting System is scientifically designed and highly reliable.

2.High temperature automatic arc melting system has the characteristics of good long-term stability and low cost of use.

3.The maximum melting temperature of Alloy smelting furnace can reach 3500℃, with a wide range.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction

The SP-MSM Series Multi-Station Suction Casting Melting Furnace is an advanced arc-melting and suction-casting system designed specifically for alloy structure analysis and phase diagram research. The system supports 8, 16, or 32 melting stations, enabling multiple samples to be melted and suction-cast simultaneously, significantly improving research efficiency.

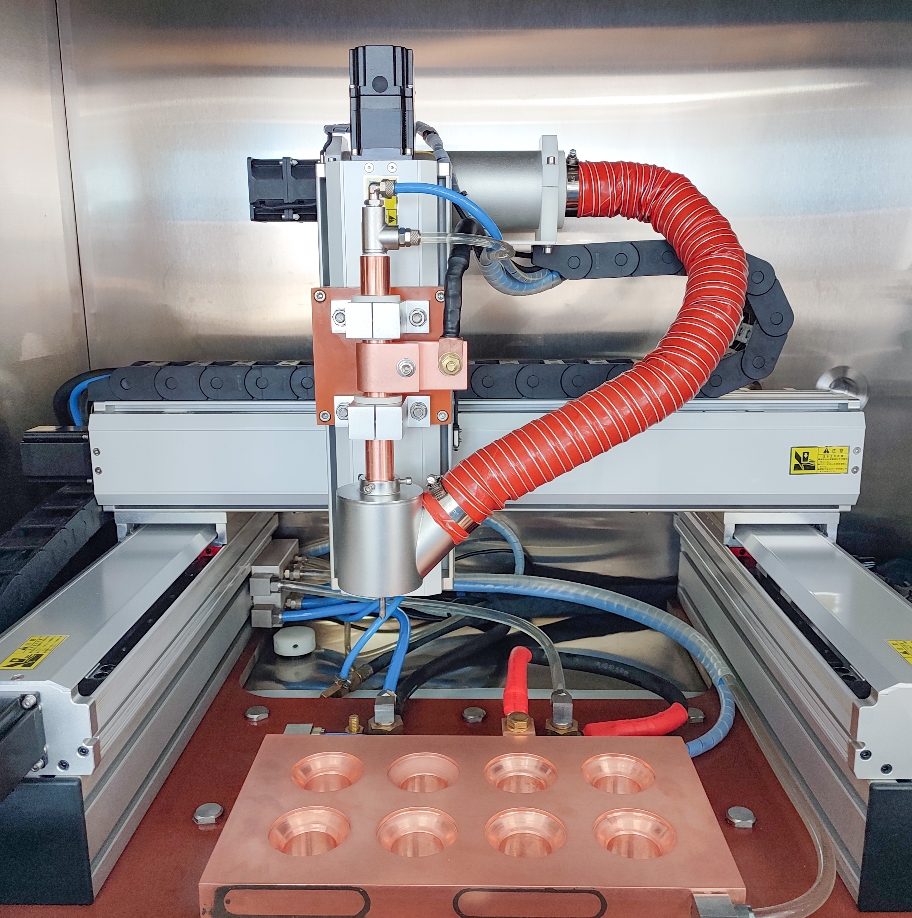

The system integrates a glove box, an X-Y-Z movable working platform, and a high-temperature arc melting module. With state-of-the-art arc heating technology, the maximum melting temperature reaches 3500 °C, ensuring precise control over melting behavior and alloy composition.

With a scientifically optimized structure, excellent long-term stability, and low operating cost, the SP-MSM series is an ideal platform for new materials development, high-temperature alloy research, and other demanding scientific applications.

Main Features

· The instrument is scientifically designed with high reliability. It offers excellent long-term stability and low operating costs.

Advantages of Alloy Smelting Furnace:

1.SP-MSM Series Multi-Station Suction Casting Melting Furnace can be used for both smelting and suction casting.

2.High temperature automatic arc melting system's dry pot can also be customized to other sizes according to your needs to meet your needs.

3.The electric lifting platform control handle of Alloy Smelting Furnace moves up and down, and the operating rocker rotates flexibly. It is simple to operate and easy to use.

Introduction of alloy smelting furnace:

Alloy smelting furnace can be equipped with magnetic stirring system to achieve uniform mixing of metal liquid flow state, so as to avoid possible defects such as steam drum and inclusion. Suction casting and pouring system kits can also be selected to achieve the production of rod samples with different diameters. Both suction casting diameter and pouring diameter can be customized with a full range of varieties. Alloy smelting furnace can be used for the preparation, purification and mixing of new alloy materials, such as high-temperature alloys.

Parameters of SP-MSM Series Multi-Station Suction Casting Melting Furnace

| Product name | SP-MSM Series Multi-Station Suction Casting Melting Furnace | |

| Product Model | SP-MSM | |

Installation conditions of 8-Station Automatic Arc Melting System | 1. Ambient temperature: 10℃~40℃ (please install air conditioner if necessary); 2. Ambient humidity: <75%; 3. Power supply: AC380V, three-phase, 50/60Hz, must be well grounded; 4. Equipment power: less than 27KW; 5. Water supply: water pressure 0.2MPa~0.4MPa, water temperature 15℃~25℃, 70L/min (provided by water chiller) (pure water or deionized water is recommended for self-circulating cooling water); 6. Ground: solid and flat; | |

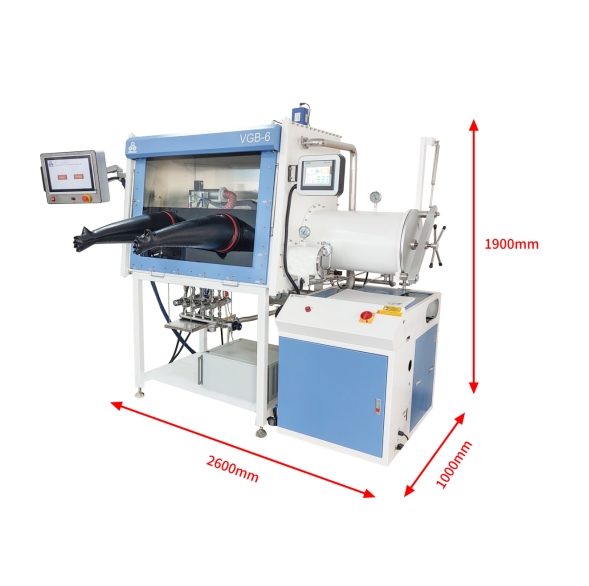

Main parameters of high temperature automatic arc melting system | Glove box 1.Size: 1200×900×750mm, single side front window. Transition compartment: 360×600/150×300mm. 2.Single column purification, equipped with circulating fan with automatic cleaning function. The gas purification system and automatic water purification system can reduce the moisture and oxygen in the glove box to below 1ppm. 3.The dew point meter and oxygen analyzer (0-999ppm) are installed inside the glove box with an accuracy of ±0.1ppm. 4.A heating module is installed in the circulation system to regenerate the dehydrating agent and deoxidizing agent. 5.The automatic pressure control system can keep the air pressure in the glove box constant. 6.The operation of the circulation system is controlled only by a color touch screen. Arc melting 1.Tungsten electrode: diameter Ø6mm, with cold water pipeline; (manual melting tungsten electrode: diameter φ4, also with cold water pipeline). 2.Maximum adjustment stroke of tungsten electrode: ≤X360×Y190×Z85mm. 3.Water-cooled crucible: Ø50×H10mm, a total of 8 melting suction casting crucibles, suction casting mold: Ø8×H75mm. 4.Maximum melting temperature: 3500℃. 5.Rated input capacity of power supply: 24.5kVA. 6.Rated no-load voltage of power supply: 65V. 7.Conventional working voltage of power supply: 34V. 8.Power supply current adjustment range: 20-630A. 9.Gas filling: Argon (box cleaning), Argon/Hydrogen mixed gas (reduction purification column purification, 0-95% Ar, 5-10% H2), purity 99.999%, H2O ≤5ppm, O2 ≤5ppm or better. 10.Arc starting method: high frequency arc starting. 11.Net weight of the main unit: about 550kg. | |

Product specifications: 2600mm (length) × 1900mm (height) × 1000mm (depth) |

| |

Company Introduction:

Kejing's product positioning is the research market, mainly for universities, scientific research institutions, laboratories and small-scale production in factories. We have established good business relations with many universities and research institutes across the country. Universities, scientific research institutions and enterprises are our long-term customers. In order to better serve customers, we have also established a high-quality customer service system as a guarantee. Customers can bring samples to our company and conduct trial processing in our laboratory to enable customers to understand the performance of our products; our staff can also provide advice and suggestions so that customers can buy suitable equipment.