Compact Vacuum Arc Melting System With 7 Cavities

MSM20-7 (Non-Consumable) Compact Metal Melting Furnace is a small high vacuum arc melting furnace. It is an ideal equipment for preparing metal and alloy samples in universities and research institutes, and can be used for preparation, purification and mixed applications of new alloy materials, such as high-entropy alloys, and high temperature alloys, etc.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction

The SP-MSM20-7 (Non-Consumable Type) Compact Metal Arc Melting Furnace is a high-vacuum, non-consumable arc melting system designed for laboratory-scale metal and alloy preparation. It is equipped with a visual vacuum gauge, allowing direct observation of the chamber pressure during operation.

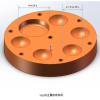

This furnace enables multiple remelts of alloy ingots without breaking the protective gas atmosphere and can simultaneously melt up to seven samples, significantly improving experimental efficiency. Its compact size, simple operation, and high sample throughput make it an ideal choice for universities and research institutes involved in the preparation, purification, and synthesis of novel metallic and alloy materials, including high-entropy alloys, high-temperature alloys, and other advanced compositions.

The SP-MSM20-7 adopts a tungsten needle electrode, featuring an ultra-high melting point and generating an arc temperature up to 3500°C, capable of melting almost all metals. To ensure operational safety and durability, both the electrode and crucible are cooled by a circulating water system during the melting process.

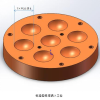

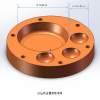

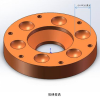

The system features a vacuum chamber of Ø200 mm × 300 mm and seven melting crucibles, each with a cavity of Ø25 mm × 8 mm depth. The maximum melting temperature reaches 3500°C. The standard configuration includes a rotary vane pump achieving a vacuum level of 10⁻³ mbar, while an optional molecular pump system can reach 10⁻⁵ mbar for ultra-high vacuum applications.

Combining precision, efficiency, and versatility, the SP-MSM20-7 Compact Arc Melting Furnace is an excellent solution for metallic material research, alloy development, and small-scale production under controlled vacuum or inert gas environments.

Main Features

1. It is equipped with a Ø120mm furnace door, which is convenient for taking and placing samples

2. It is equipped with front and rear observation windows, which is convenient for observing the arcing and melting state.

3. The vacuum chamber, copper crucible and arcing electrode are all cooled by water.

4. The up and down movement adopts steering wheel design, and the operation rocker is flexible.

5. In order to ensure that the alloy ingot can be turned over for multiple smelting without destroying protective atmosphere, a manipulator turn-over mechanism is used in the melting furnace.

6. The crucible is small in size and large in quantity, which can facilitate the production of multiple samples and avoid mutual contamination between samples.

7. Simple to operate, safe and convenient, compact in design, covering less space

Chamber door | Front observation window | Rear observation window | Turn-over manipulator | Consumable electrode (for placing flashlight) | Electrode control (arc ignition and current regulation) |

| | | | |

|

Technical Parameters

Product Name | SP-MSM20-7 (Non-Consumable) Compact Metal Melting Furnace | |

| Product Model | SP-MSM20-7 | |

Installation Conditions | This equipment is required to be used at a temperature of 25℃±15℃, and a humidity of 55%Rh±10%Rh. 1. Water: The equipment is equipped with a self-circulating cooling water machine (filled with pure water or deionized water) 2. Electricity: AC380V 50Hz (63A air switch), must have good grounding 3. Gas: The equipment chamber needs to be filled with argon gas (purity 99.99% or more), and argon gas cylinders are required (with Ø6mm double ferrule joints) 4. Workbench: floor type, 900mm×600mm×700mm, bearing more than 200kg 5. Ventilation device: needed | |

Major Parameters (Specification) | 1. Power supply: AC380V 50Hz 2. Power of the whole machine: <12kW 3. Vacuum chamber: Ø200mm×300mm 4. Crucible: 7 melting cavities, Ø25mm depth of 8mm (special size can be customized according to customer requirements.) Standard 7 crucibles customized non-standard size crucibles 5. Vacuum degree: standard rotary vane pump can reach 10-3mbar, optional molecular pump of our company can reach 10-5mbar 6. Non-consumable arcing electrode: tungsten needle (W) 7. Scope of application: It can be used to smelt metal materials with a melting point lower than tungsten 8. Melting temperature: up to 3500℃, which can melt almost all metals 9. Output current: 20-315(A) 4.5g tungsten melt sample 10g metal tungsten melt sample | |

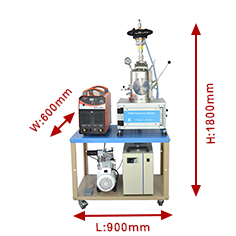

| Product Dimension and Weight | Dimension: 900mm×600mm×1800mm (including furnace frame) Weight: 50kg |  |

Optional Functions | 1. Metal smelting pipe sealing kit

| 2. Compact metal melting and suction casting furnace (MSM20-8) |

Standard Accessories | 1. Main Machine: 1 set 2. VRD Rotary Vane Mechanical Pump and Connecting Pipeline: 1 set 3. KJ-5000 Chiller/Water Cooler: 1 pcs | |

Optional Accessories | 1. High Vacuum System GZK-103D 2. EQ-PCG-554 Anti-Corrosion Digital Vacuum Gauge ( range of measurement: 3.8 × 10-5torr to 1125 Torr) | |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics