Small DC Magnetron Plasma Sputtering Machine

1. This Lab DC Magnetron Sputtering Coater is specifically designed for metal coating needs and can be used with a variety of metal materials.

2. The sample stage of this Lab DC Magnetron Sputtering Coater is height-adjustable, allowing it to accommodate samples of varying sizes.

3. This Lab DC Magnetron Sputtering Coater can be optionally used with our high vacuum unit to achieve even higher vacuum levels.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of Lab DC Magnetron Sputtering Coater Machine:

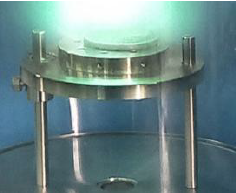

The VTC-16-D Magnetron Sputtering Coater is a small DC magnetron plasma sputtering coater with a 2-inch target head diameter and an adjustable sample stage. This small magnetron plasma sputtering instrument is primarily designed for producing metal films. With its compact size and high cost-effectiveness, it is an ideal coating system for various metal thin films.

Key Features of the Lab DC Magnetron Sputtering Coater Machine:

· The Magnetron Sputtering Coater is compact, simple to operate, and easy to use.

· Small magnetron plasma sputtering instrument features a small magnetic control target head and can coat metals such as gold, silver, and platinum.

Technical Parameters of the Small Magnetron Plasma Sputtering Instrument:

| Product Name | VTC-16-D Single-Target Small magnetron plasma sputtering instrument | |

| Model | VTC-16-D | |

| Basic Specifications | 1. Input Power of Small magnetron plasma sputtering instrument: 220V AC 50/60Hz 2. Power of Lab DC Magnetron Sputtering Coater Machine: <1000W 3. Output Voltage of Lab DC Magnetron Sputtering Coater Machine: DC 500V 4. Sputtering Current: 0-80mA, adjustable 5. Sputtering Time: 0-120s, adjustable | |

| Sputtering Chamber | 1. Quartz Chamber Dimensions: OD 166mm × ID 150mm ×Height 150mm 2. Seal: Fluorine rubber O-ring 3. A manually operable shutter is installed on the flange cover for pre-sputtering the target. A 6.35mm Ø compression fitting serves as the air inlet port for connecting the air inlet pipe. A manual air bleed valve is used to fill the quartz chamber with air. 4. A stainless steel mesh covers the entire quartz chamber to shield the plasma.

| |

5. The flow of working gas into the chamber is controlled by adjusting the micro-precision control valve on the right side of the housing, thereby adjusting the vacuum level within the chamber. 6. The sputtering current is controlled by adjusting the potentiometer on the right side of the housing.

| ||

| Target Head and Target Material | 1. A 2-inch magnetron sputtering target head without water cooling. The maximum operating temperature of the magnetron sputtering target head is 80 degrees Celsius. Above 80 degrees Celsius, the magnetron sputtering target head will lose its magnetism and become inoperable. 2. Sputtering time: Adjustable from 1 to 120 seconds 3. Standard copper target included 4. Target size requirement: φ2" x (0.5-5) mm thickness 5. Suitable for sputtering Au, Ag, Cu, and other metals (available for purchase at our company). | |

| Sample Stage of Lab DC Magnetron Sputtering Coater Machine | 1. A sample stage with adjustable height, with an adjustable distance between the sample stage and the target of 25-70 mm. 2. Sample stage size: φ2" 3. Optional sample stage heating, with a maximum heating temperature of 500°C.

| |

| Pirani Vacuum Gauge | 1. Measuring range: 1 × 10-4 mbar to 1000 mbar (1 × 10-4 to 750 torr) 2. Accuracy: 1000 mbar to 20 mbar (30% of reading) 20 to 0.002 mbar (2% of reading) 3. Repeatability: 20 to 0.002 mbar (0.000 to 0.002 mbar) 2%) 4. Operating humidity: ≤80% at 30°C, ≤50% at 40°C, no condensation; 5. Operating temperature: 5°C-60°C |

|

| Thin Film Thickness Gauge (Optional) | 1. A precision quartz vibrating film thickness gauge is installed on the instrument, enabling real-time monitoring of film thickness with a resolution of 0.10 Å. 2. The LED display provides both display and input of film thickness data.

| |

| Vacuum System (Optional) | 1. Model: VRD-8 2. Pumping rate: 2.2 L/s 3. Motor power: 370 W 4. Ultimate pressure: 5 × 10-1 Pa (unloaded) 5. Actual pressure: ≤ 5 Pa (mechanical pumping for 20 minutes under cold conditions) |

|

6. For higher vacuum levels (10-5 tons or better), domestic or imported high vacuum units are available.

| ||

| Specifications of Lab DC Magnetron Sputtering Coater Machine | Dimensions: 500mm × 350mm × 550mm (L × W × H) Weight: Approximately 20kg (excluding vacuum pump and water cooling equipment) |

|

| Equipment Usage Requirements | 1. Multiple sputtering cycles are required to achieve the desired film thickness. 2. Before sputtering, ensure the sputtering head, target, substrate, and sample stage are clean. 3. To ensure good adhesion between the film and the substrate, clean the substrate surface before sputtering. | |

| Warranty Period | One-year warranty and lifetime technical support. Special Notes: 1. Consumables such as heating elements, quartz tubes, and sample crucibles are not covered by the warranty. 2. Damage caused by the use of corrosive and acidic gases is not covered by the warranty. | |

| Precautions | · The pressure inside the chamber must not exceed 0.02 MPa (relative pressure). · Because the internal pressure of the gas cylinder is relatively high, a pressure reducing valve must be installed on the cylinder when introducing gas into the quartz tube. To ensure safety, we recommend operating the pressure below 0.02 MPa. We recommend purchasing a pressure reducing valve from our company, which has a range of 0.01 MPa-0.1 MPa, for greater accuracy and safety. · We do not recommend the use of flammable, explosive, or toxic gases. If your process requires the use of flammable, explosive, or toxic gases, please implement appropriate protective and explosion-proof measures. Our company is not responsible for any problems caused by the use of flammable, explosive, or toxic gases. | |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. | |

About us:

If you purchase our products for your own use, you will enjoy precision, reliability, convenience, and efficiency.

We offer customized services. You can find a variety of models with varying specifications on our website, allowing you to select the equipment that best suits your project. Alternatively, you can contact us for equipment recommendations and receive a satisfactory response.

Our goal is to provide customers with intelligent, energy-efficient, and environmentally friendly equipment that meets today's demands for high efficiency and sustainable development.

After your purchase, we provide after-sales service. We are fully responsible for any unforeseen malfunctions. We are also willing to assist with any concerns or questions you may have during use.

The application requirements of Plasma Thin Film Sputtering Instruments are becoming increasingly diverse across various industries. With our strong R&D capabilities and industry insights, we have developed this efficient, precise, and stable Plasma Thin Film Sputtering Instrument to help customers improve product quality, reduce production costs, and lay a solid foundation for the future development of thin film technology.

Regarding equipment, we provide you with rigorously inspected and tested equipment.

Regarding service, we offer comprehensive services to enhance your trust.

Regarding collaboration, we look forward to long-term cooperation with you, improving our technical level, and fully supporting your projects.