NanoFiber Electrospinning System With High Voltage

Electrospinning is a simple and effective process, with the action of a high-voltage electric field, for spinning polymer solutions or melts into fine fibers with dimensions ranging from micrometers to nanometers, namely polymer jet electrospinning.

It can be used for preparation of biopolymers, commodity polymers, and prepolymer nanofibers; preparation of polymer blend nanofibers; preparation of surfaces or films with nanopores, nanoparticles, and nanobeads.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Product Introduction

This equipment utilizes electrospinning technology, in which a high-voltage electric field draws polymer solutions or melts into ultrafine fibers with diameters ranging from the micrometer scale down to the nanometer scale. It is suitable for producing nanofibers from biopolymers, general polymers, prepolymers, and polymer blends. Compared with conventional spinning techniques, electrospinning generates much finer fibers—typically several tens to thousands of nanometers—and produces interconnected porous nanofiber membranes with extremely large specific surface areas. The fiber surfaces often exhibit nanopores, nanoparticles, or bead-on-string microstructures, resulting in strong adsorption capacity and excellent filtration, barrier, adhesion, and thermal-insulation properties.

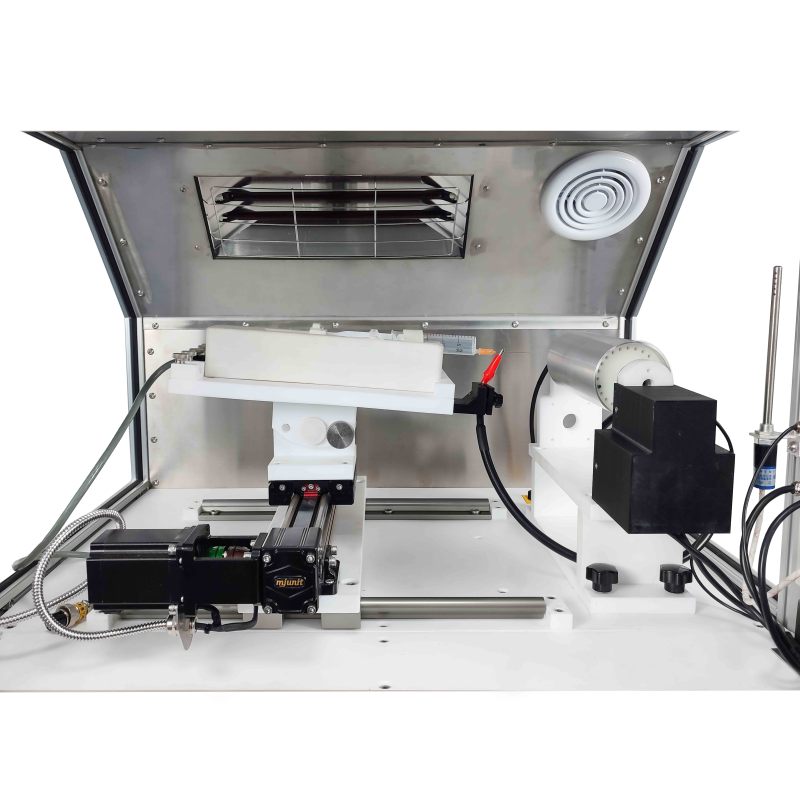

The system features a fully enclosed spinning chamber constructed with corrosion-resistant materials and equipped with positive/negative pressure control and an exhaust system. Key parameters such as temperature, flow rate, and collector speed can be precisely regulated to reduce fiber drifting and improve fiber uniformity. A wide selection of spinnerets, collectors, and syringe pumps is available to meet various research requirements, including the fabrication of nanoporous surfaces, nanoparticle-decorated fibers, and bead-on-string nanostructured films. This equipment is ideal for universities, research laboratories, and advanced materials development institutions.

Main Application Fields:

Biopolymer, general polymer, and prepolymer nanofiber fabrication; polymer-blend nanofibers; functional surfaces and films with nanoporous, nanoparticle, or bead-on-string nanostructures.

Main Features

1. Equipped with positive and negative high voltage, the voltage is continuously adjustable to ensure accurate voltage

2. The whole machine is made of anti-corrosive materials

3. Capable of preparing stable and uniform nanofiber membrane

4. There is no additional electric field interference inside the chassis, the spinning voltage is stable, and there is no wire.

5. A variety of nozzles and yarn collectors can be optional.

6. Optional multi-channel injection pump (single-channel, dual-channel, five-channel, etc.)

7. The liquid injection pump is specially designed for electrospinning, and the thrust is 3 times that of ordinary medical injection pump, which can be used for high viscosity liquids. High pressure working environment, suitable for transferring various liquids for electrospinning.

Technical Parameters

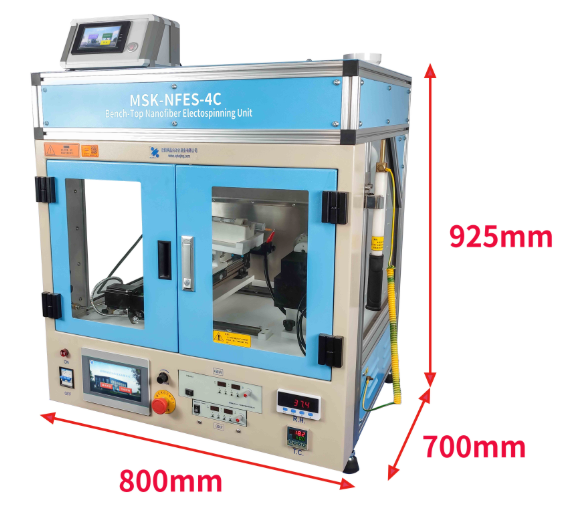

| Product Name | MSK-NFES-4C Bench-Top Electrospinning Machine/Unit | ||

| Product Model | MSK-NFES-4C | ||

| Installation Requirements | 1. Temperature & Humidity:10–85% RH (at 25°C, non-condensing); operating temperature: 5–45°C. 2. Environment:The equipment must be placed away from strong vibration sources and corrosive gases, with at least 200 mm of clearance around the unit. 3. Water Supply:Not required. 4. Power Supply:Single-phase AC220V, 50Hz, three-pin socket, 16A, with reliable grounding. 5. Air Supply:Not required. 6. Workbench:Recommended size: 1000 × 800 × 550 mm, placed on a sturdy platform capable of supporting at least 180 kg. 7. Ventilation:The device can be connected to an exhaust duct depending on process requirements. | ||

| Technical Specifications | Main Unit | 1. Power Input:Single-phase AC220V, 50Hz, 16A 2. Total Power:2350 W 3. Construction:Aluminum alloy frame + sheet metal housing 4. Nozzle Stage X-Axis Travel:Manual movement: effective travel 1–100 mm 5. Nozzle Stage Y-Axis Travel: · Tuning interface: effective travel 1–280 mm · Automatic control:effective travel 1–220 mm 6. Y-Axis Motorized Speed:1–10 mm/s 7. Nozzle Stage Tilt Adjustment:Manual fine adjustment | |

| 8. Collector Size:Φ80 × 200 mm 9. Collector Rotational Speed · Setting range: 30–4400 rpm ±100 rpm |  | ||

| 10. High-Voltage Power Supply (Positive) · Max voltage: +50 kV High-Voltage Power Supply (Negative) · Max voltage: –30 kV 11. HV Output Stability:After 30 min warm-up, stability better than 0.1% over 8 hours 12. Voltage/Current Display Accuracy: · Three-digit display · Voltage accuracy: ±(0.5% + 1 digit) · Current accuracy: ±(4% + 3 digits) 13. Heating Temperature:RT–50°C 14. Heating Power:1800 W 15. Condensation & Dehumidification Power:280W 16. Exhaust Port:Φ100 mm 17. Control System:7-inch touchscreen + positive/negative HV power controls + AT intelligent temperature controller + humidity controller | |||

18. Product Specifications · Overall Dimensions:800 × 700 × 925 mm · Total Weight:140kg |  | ||

| Syringe Pump System | 1. Pump Power Input:DC24V (Standard power adapter: IN AC100–240V 50/60Hz; OUT DC24V 3.75A) 2. Pump Power:≤50 W 3. Injection Speed:0.001–20 mm/min 4. Fine Adjustment Speed:0.001–10 mm/min 5. Syringe Diameter:0.04–30 mm 6. Syringe Volume · Standard: 20 mL 7. Stroke Setting Range:0.01–90 mm 8. Control Method:4.3-inch touchscreen independent control (supports synchronized operation with main unit) 9. Pump Dimensions:250 × 65 × 50 mm | ||

| cautions | 1. Make correct wiring before use. Read the instruction manual carefully. 2. Check and confirm that all wiring is correct before starting the device. 3. Turn on the lighting, temperature and exhaust switches on the control interface to confirm whether the lighting, heating and exhaust systems in the box work properly. 4. Connection and inspection of high voltage power supply. Before use, check whether the high-voltage output line and the nozzle are well connected, and whether the polarity is correct; when using the voltage adjustment button for the first time, turn it counterclockwise to the end, turn on the power supply and turn the adjustment button clockwise to increase the voltage. At this time, the display shows voltage and current value respectively. 5. When debugging of the syringe pump, use touch screen to debug whether the syringe pump is running normally. 6. When loading electrospinning solution, use syringe to fill the solution manually. 7. During electrospinning operation, it is strictly forbidden to open the door of the box without cutting off high-voltage DC power supply, or touch the metal needle of the electrospinning spinneret with hands, which may cause damage to human body by high-voltage DC power supply. When high-voltage DC power supply is not cut off due to the needs of electrospinning, the metal needle must be moved with an insulator material. 8. When the electrospinning machine works abnormally, high-voltage DC power supply should be turned off immediately, and should be checked by professional and technical personnel. Normal electrospinning can only be carried out after troubleshooting. 9. When adjusting voltage, slowly adjust it clockwise to the required voltage value. When turning off the power supply, turn the power supply voltage (rotary) button counterclockwise to the end (to the 0 position) and turn it off. 10. When the cabinet door is opened, high-voltage power supply and other equipment should stop working. When replacing the electrospinning liquid for the injection pump in the electrospinning box, high-voltage DC power supply must be turned off first. 11. Before sampling, the discharge rod should be in contact with the collector to impose accumulated electric charge onto the sample. Discharge to the ground to ensure personal safety. 12. This equipment is not suitable for electrospinning strong corrosive solution. | ||

Standard Accessories

| No. | Name | Quantity | Image |

| 1 | Syringe Pump (Note: An additional syringe pump can be purchased; please consult sales in advance.) | 1 unit |  |

| 2 | Droppers | 2 pcs | |

| 3 | Rotating Drum Collector with Sliding Stage | 1 set | |

| 4 | Discharge Rod | 1 pc |

Optional Accessories

| No. | Name | Function Category | Image | |

| 1 | Syringe Pump (Note: One additional syringe pump may be purchased; please contact sales in advance.) | Optional |  | |

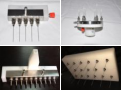

| 2 | Electrospinning Spinnerets | Coaxial Spinneret | Optional |  |

| Side-by-Side Spinneret | Optional |  | ||

| Parallel Spinneret | Optional |  | ||

Multi-Spinneret (linear, circular, or array arrangement) | Optional |  | ||

| Three-Core Spinneret | Optional |  | ||

| Two-Core Spinneret | Optional |  | ||

| 3 | Electrospinning Collectors | Parallel Electrode Collector |  | |

| Cage Collector |  | |||

Thin Shaft Collector (diameter range: 1–10 mm) |

| |||

| Disc Collector |  | |||

| Thick Disc Collector |  | |||

| Magnetic Electrode Collector |

| |||

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics