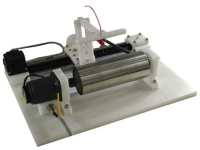

Bench-Top NanoFiber Electrospinning System

Electrospinning is a simple and effective process, with the action of a high-voltage electric field, for spinning polymer solutions or melts into fine fibers with dimensions ranging from micrometers to nanometers, namely polymer jet electrospinning.

It can be used for preparation of biopolymers, commodity polymers, and prepolymer nanofibers; preparation of polymer blend nanofibers; preparation of surfaces or films with nanopores, nanoparticles, and nanobeads.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Product Introduction

This equipment utilizes electrospinning technology, in which a high-voltage electric field draws polymer solutions or melts into ultrafine fibers with diameters ranging from several tens of nanometers to a few micrometers. Compared with conventional spinning methods, electrospinning produces much finer fibers and interconnected porous nanofiber membranes with extremely large specific surface areas. The surfaces of these fibers often feature multi-level microstructures such as nanopores, nanoparticles, and bead-on-string morphologies, providing excellent adsorption capability as well as superior filtration, barrier, adhesion, and thermal insulation properties.

The system adopts a fully enclosed spinning chamber and allows precise control of key process parameters such as temperature, flow rate, and collecting speed, effectively reducing fiber drifting and improving fiber uniformity. Multiple types of spinnerets and collectors are available to meet diverse research needs. It is suitable for producing nanofibers from biopolymers, general polymers, prepolymers, and polymer blends, as well as for fabricating surfaces or films with nanoporous, particulate, or bead-on-string structures. This equipment is ideal for universities, research institutes, and advanced material development laboratories.

Technical Parameters

| Product Name | MSK-NFES-3C Bench-Top Electrospinning Machine/Unit | |

| Product Model | MSK-NFES-3C | |

Major Parameters (Specification) | Main Unit Specifications |

|

Syringe Pump System

|

| |

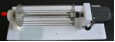

Rotating Drum Collector

|

| |

Flat Plate Collector (Optional / Customizable)

|

| |

Standard Accessories

| No. | Name | Quantity | Image |

| 1 | Syringe Pump | 1 set | - |

| 2 | Droppers | 5 pcs | - |

| 3 | Rotating Drum Collector with Sliding Stage | 1 set | - |

| 4 | Infusion Tubes (with needles) | 5 pcs | - |

| 5 | Discharge Rod | 1 pc | - |

Optional Accessories

| No. | Name | Function Category | Image | |

| 1 | Collection Platform | Optional | - | |

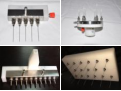

| 2 | Electrospinning Spinnerets | Coaxial Spinneret | Optional |  |

| Side-by-Side Spinneret | Optional |  | ||

| Parallel Spinneret | Optional |  | ||

Multi-Spinneret (linear, circular, or array arrangement) | Optional |  | ||

| Three-Core Spinneret | Optional |  | ||

| Two-Core Spinneret | Optional |  | ||

| 3 | Electrospinning Collectors | Parallel Electrode Collector | Optional |  |

| Cage Collector | Optional |

| ||

Thin Shaft Collector (diameter range: 1–10 mm) | Optional |

| ||

| Disc Collector | Optional |  | ||

| Thick Disc Collector | Optional |  | ||

| Magnetic Electrode Collector | Optional |

| ||

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics