Lapping And Polishing Machine With Center Pressure Example

1. Lapping And Polishing Machine With Center Pressure is versatile and widely applicable.

2. Lapping And Polishing Machine With Center Pressure can be customized according to customer needs.

3. Lapping And Polishing Machine With Center Pressure has a high degree of automation.

- Information

Product Introduction

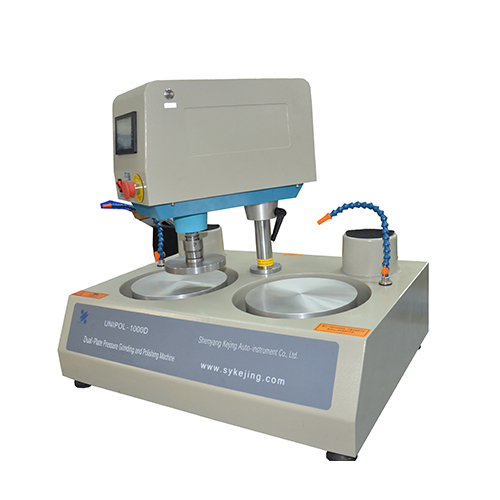

The UNIPOL-1200S Automatic Pressure Grinding and Polishing Machine is primarily designed for material research applications. It is widely used in universities, research institutes, and laboratories for the automatic grinding and polishing of various materials, including metals, ceramics, glass, infrared optical materials (such as ZnSe, ZnS, Si, Ge crystals), rock and mineral samples, composite materials, and organic polymers. It is also suitable for small-scale production in factories.

The UNIPOL-1200S adopts a mechanical pressure-loading system, ensuring that samples are subjected to a constant and uniform pressure during the grinding and polishing process. The machine is equipped with a mechanical arm polishing station, enabling it to perform high-pressure grinding and polishing of superhard materials, as well as gentle, controlled processing of cleavable or fragile materials. This design significantly expands the versatility and application range of the equipment.

Additionally, the UNIPOL-1200S allows users to preset grinding and polishing time; once the set duration is reached, the system automatically stops operation, enabling unattended or automated processing for improved efficiency and safety.

Product features of Lapping And Polishing Machine With Center Pressure:

1. Our Grinding machine is specially equipped with a mechanical arm grinding and polishing workstation.

2. This polishing machine uses centralized loading pressure, and the pressure is stable and reliable.

3. This Grinder with Power Head has excellent performance, simple operation and wide application range.

Technical parameters of Lapping And Polishing Machine With Center Pressure:

Product Name | UNIPOL-1200S Automatic Pressure Grinding and Polishing Machine |

Product Model | UNIPOL-1200S |

Installation Conditions | Lapping And Polishing Machine With Center Pressure is required to be used at an altitude of 1000m or less, a temperature of 25℃±15℃, and a humidity of 55%Rh±10%Rh. 1. Water: The equipment is equipped with water inlet and water outlet, and needs to be connected to the tap water and drainage by users. 2. Electricity: AC220V 50Hz, must have good grounding 3. gas: N/A 4. Workbench: size 800mm×600mm×700mm, bearing more than 200kg 5. Ventilation device: no need |

Main Parameters (Specification) | · Power Supply Port: AC 220V, 50Hz · Total Power: 550W · Grinding/Polishing Disc Diameter: Φ300 mm · Quick-Mount Sample Holder Diameter: Φ160 mm · Gravity Sample Holder Diameter (Flat): Φ105 mm · Lower Swing Station (Oscillating Mechanical Arm): 1 station · Upper Plate Main Drive Motor: DC 110V, 90W (gear motor) · Lower Plate Main Drive Motor: DC 110V, 400W · Upper Sample Holder Rotation Speed: 10–80 rpm (adjustable) · Lower Grinding/Polishing Disc Rotation Speed: 20–240 rpm (adjustable) · Upper Sample Holder Pressure Range: 0.5–20 kg (adjustable setting) · Control System: PLC controller + touch screen |

Product Dimension and Weight | Dimension: 460mm×660mm×760mm; weight: 95kg

|

Lapping And Polishing Machine With Center Pressure Application areas:

1. UNIPOL-1200S Automatic Pressure Grinding and Polishing Machine is mainly used in the field of materials research and is widely used in laboratories of universities and scientific research institutes to automatically grind and polish samples of metal, ceramics, glass, and infrared optical materials (such as zinc selenide, etc.) UNIPOL-1200S fully automatic pressure grinding and polishing machine uses mechanical pressurization, which can keep the sample under constant pressure during the grinding process.

2. Grinder with Power Head can be used in the automotive industry and can be used for surface treatment of automotive parts, such as engine blocks, cylinder liners, etc.

3. Polishing machines can be widely used in the manufacturing industry and can be used for surface processing and surface treatment of metal products such as molds and knives.

4. Lapping And Polishing Machine With Center Pressure can be configured with different specifications and models of grinding heads, automation devices, processing fluid circulation systems, etc. according to your needs to meet different production requirements and process needs.

Standard accessories for Lapping And Polishing Machine With Center Pressure:

No. | name | qty | picture |

1 | Cast Iron Polishing Plate | 1 pcs | |

2 | Cast Aluminum Polishing Plate | 1 pcs |

|

3 | Sample Holding Plate | 1 pcs | |

4 | Gravity Sample Plate | 1 pcs | |

5 | Condition Ring | 1 pcs |

|

6 | Magnetic Sheet | 2 pcs | |

7 | (Steel) Lapping Buffer Sheet | 2 pcs | |

8 | Sandpaper (240#, 400#, 800#, 1500#) | 2 pcs each | |

9 | Polishing Pad (Nubuck Leather, Synthetic Leather, Polyurethane) | 1 pcs each | |

10 | Diamond Polishing Paste (W2.5) | 1 pcs |

|

Optional accessories for Lapping And Polishing Machine With Center Pressure:

No. | name | functional type | picture |

1 | SKZD-2 Slurry Feeder | (optional) |

|

2 | SKZD-3 Slurry Feeder | (optional) | |

3 | SKZD-4 Automatic Slurry Feeder | (optional) | |

4 | SKZD-5 Slurry Feeder | (optional) | |

5 | YZXZ-12 Stirring Circulation Pump | (optional) | |

6 | Precision Thickness Gauge | (optional) | |

7 | GPC-80A Precision Polishing Controller | (optional) | |

8 | Ceramic Lapping Plate | (optional) | |

9 | Glass Lapping Plate | (optional) | |

10 | Magnetic resin diamond polishing disc | (optional) | |

11 | Wax-free lapping plate | (optional) | |

12 | Peach-shape hole sample holding plate (φ105mm) | (optional) | |

13 | Special fixture for UNIPOL-1200S pressure lapping machine | (optional) |

|

Warranty date:

One year limited, lifetime support (excluding parts rusted due to insufficient storage conditions)

Logistics and freight: