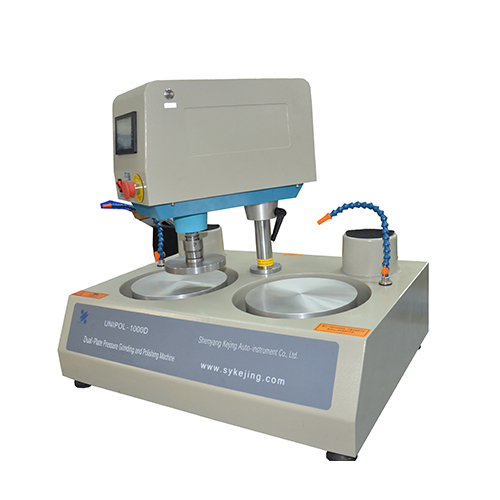

High Throughput Pressure Lapping And Polishing Machine

UNIPOL-1500M-16 Automatic Pressure Grinding and Polishing Machine is mainly used in the field of material research, and is suitable for automatic grinding and polishing samples of metal, ceramics, glass, infrared optical materials (such as zinc selenide, zinc sulfide, silicon, germanium), rock samples, mineral samples, composite materials, organic polymer materials as well as small-scale production in factories. UNIPOL-1500M-16 automatic pressure grinding and polishing machine is equipped with double sample plates and each sample plate can fix 6 groups of samples. Each sample plate adopts multi-point pneumatic pressure, so that it is evenly stressed and the grinding pressure is adjustable.

- Shenyang Kejing

- Shenyang, China

- 44 working days

- 50 sets

- Information

Product Introduction

The UNIPOL-1500M-16 Automatic Pressure Grinding and Polishing Machine is primarily designed for material research applications. It is suitable for the automatic grinding and polishing of a wide range of materials, including metals, ceramics, glass, infrared optical materials (such as ZnSe, ZnS, Si, and Ge crystals), rock and mineral samples, composite materials, and organic polymers. The system can also be used for small-scale production in industrial environments.

This machine features high processing accuracy, stable and reliable performance, easy operation, and broad versatility, making it an ideal choice for universities, research institutes, and manufacturing laboratories.

The UNIPOL-1500M-16 is a dual-sample-holder pressure grinding machine, with two independent sample holders, each capable of accommodating up to 8 specimens. Both holders employ a multi-point pneumatic pressure system, ensuring uniform force distribution across all samples. The grinding pressure is adjustable to suit different material properties and process requirements.

During operation, the sample holders can rotate clockwise or counterclockwise. Depending on the hardness or polishing difficulty of the material, the rotation direction can be selected accordingly. In most cases, the sample holder rotates opposite to the grinding plate, optimizing the grinding and polishing effect.

The UNIPOL-1500M-16 also allows users to preset the grinding and polishing duration. Once the set time elapses, the system automatically stops operation, enabling unattended or automated processing.

Under the action of compressed air, the pneumatic cylinders press the samples—mounted on the holders—against the rotating grinding/polishing discs, ensuring precise alignment and consistent surface finishing.

Each grinding/polishing disc has a diameter of Φ300 mm, and the dual-head configuration includes 16 sample positions with corresponding pneumatic rods (standard). The machine is suitable for mounted samples or cylindrical specimens, enabling the simultaneous and consistent preparation of multiple samples with high reproducibility.

Technical Parameters

Product Name | UNIPOL-1500M-16 Automatic Pressure Grinding and Polishing Machine / Lapping Machine |

Product Model | UNIPOL-1500M-16 |

Installation Conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around the equipment. 3. Power supply: single phase: AC220V 50Hz 10A (the socket must have a good safety protection grounding wire) 4. Cooling water: The equipment is equipped with an inlet and a drain, and you need to connect the tap water and drainage pipeline or filter circulation water tank by yourself. 5. Air source: compressed air: ≥0.5MPa 6. Workbench: It is recommended to use it on an operating table or desktop with a load of more than 200kg 7. Ventilation device: good ventilation environment, no special ventilation device requirements are required 8. Auxiliary equipment (purchased separately) Recommended: 1. SZKD-series drip feeder 2. YJXZ-12 mixing circulation pump 3. YJXZ-25 automatic filter water tank 4. Silent oil-free air compressor |

The main parameters | 1. Equipment power supply port: AC220V 50Hz 2. Total power: 1.5kW (MAX) 3. Grinding and polishing plate diameter: Φ381 mm 4. Quick card sample plate diameter: Φ150 mm (sample loading holes: 8) 5. Sample loading hole diameter: standard: Ø30mm, customizable options: Ø22-35mm (MAX) 6. Upper plate main drive motor: precision servo motor 0.2kW 7. Lower plate main drive motor: precision servo motor 1.0kW 8. Upper sample plate speed: 10-100rpm (speed adjustable) 9. Lower grinding and polishing plate speed: 50-300rpm (speed adjustment) 10. Sample loading range: pneumatic loading pressure adjustment: 0.15-0.4MPa 11. Control method: button + touch screen |

Product Dimension and Weight | Dimension: 600mm×720mm×800mm Weight: ≈125kg |

Standard Accessories

No. | name | qty | picture |

1 | Cast Aluminum Polishing Plate | 1 pcs |

|

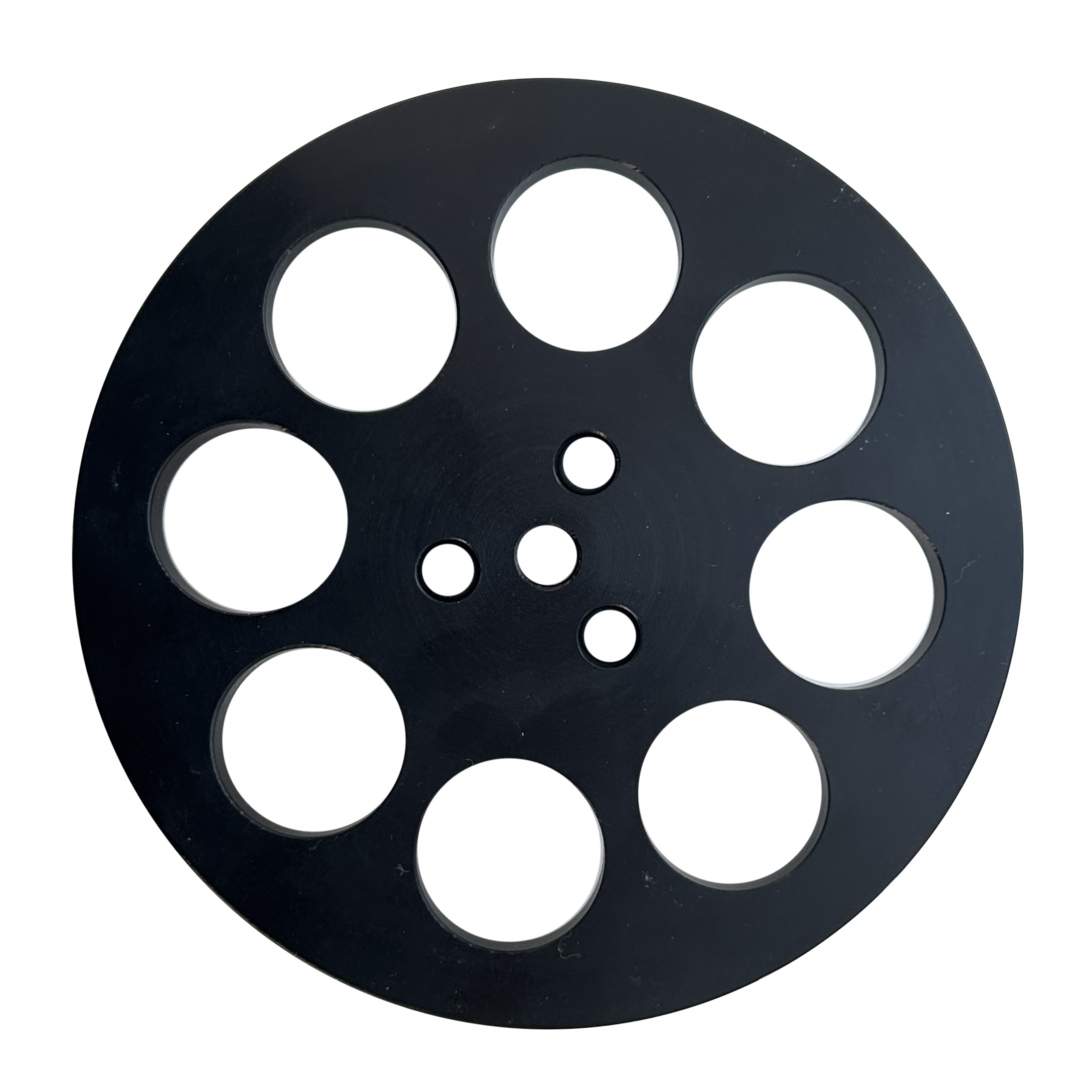

2 | Sample Holding Plate | 2 pcs |

|

3 | Magnetic Sheet | 2 pcs |

|

4 | (Steel) Lapping Buffer Sheet | 4 pcs | |

5 | Sandpaper (240#, 400#, 800#, 1500#) | 2 pcs each |

|

6 | Polishing Pad (Nubuck Leather, Synthetic Leather, Polyurethane) | 1 pcs each |

|

7 | Diamond Polishing Paste (W2.5) | 1 pcs |

|

Optional Accessories

No. | name | functional type | picture |

1 | SKZD-2 Slurry Feeder | (optional) |

|

2 | SKZD-3 Slurry Feeder | (optional) |

|

3 | SKZD-4 Automatic Slurry Feeder | (optional) | |

4 | SKZD-5 Slurry Feeder | (optional) | |

5 | YZXZ-12 Stirring Circulation Pump | (optional) |

|

6 | Ceramic Lapping Plate | (optional) | |

7 | Glass Lapping Plate | (optional) | |

8 | YJXZ-25 Auto Filtering Circulating Water Tank | (optional) | |

9 | Mute Oilless Air Compressor | (optional) |

|

Warranty

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics