Fully Automatic Metallographical Grinding And Polishing System

UNIPOL-1210S automatic pressure grinding and polishing system is mainly used in the field of material research. It is suitable for automatic grinding and polishing of metal, ceramics, glass, rock samples, mineral samples and other material samples, and can also be used for small-scale production in factories. The machine has the characteristics of high processing precision, stable and reliable performance, simple operation and wide application range. This machine is widely used in universities, research institutes and production fields.

- Shenyang Kejing

- Shenyang, China

- 44 working days

- 10 sets

- Information

Product Introduction

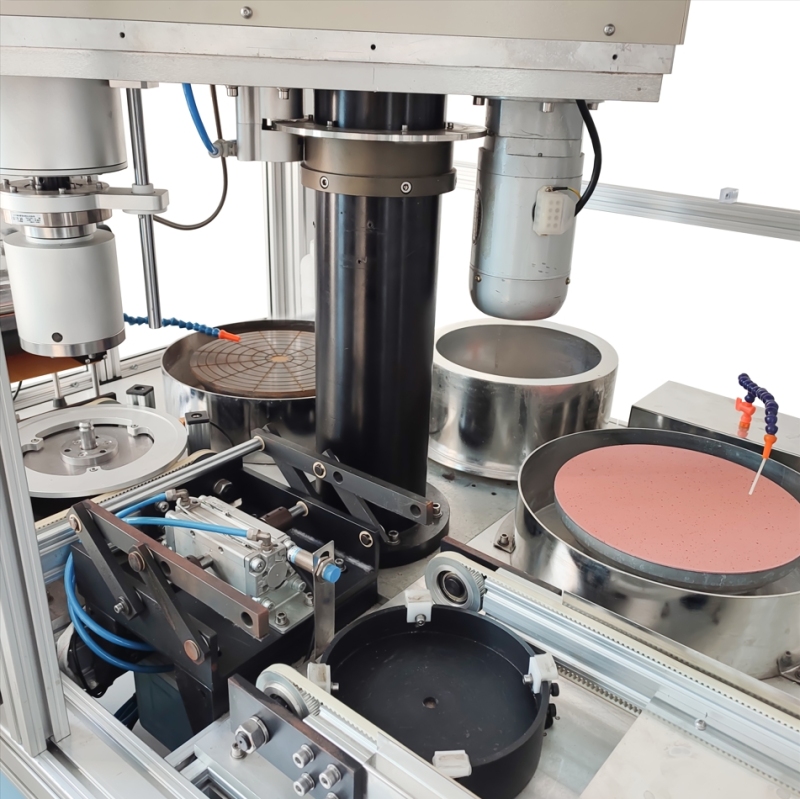

The UNIPOL-1210S Automatic Pressure Grinding and Polishing System is primarily designed for the field of materials research. It is suitable for automatic grinding and polishing of various samples such as metals, ceramics, glass, rock, and mineral specimens, and can also be applied in small-scale factory production. This system features high processing accuracy, stable and reliable performance, simple operation, and a wide application range. It is widely used in universities, research institutes, and industrial production fields.

Technical parameters:

Product Name | UNIPOL-1210S Automatic Pressure Grinding and Polishing System / Lapping System |

Product Model | UNIPOL-1210S |

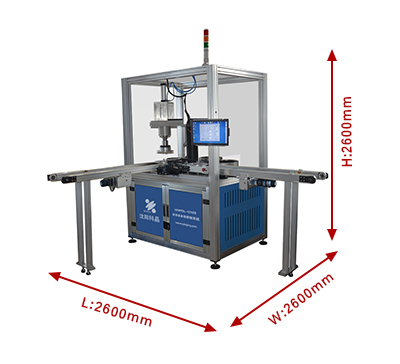

Main Parameters (Specification) | 1.Power Supply: 220V, 50Hz 2.Air Supply: Pressure 0.1–0.7 MPa 3.Water Supply: Water reservoir (provided by customer) 4.Pressure Spindle Speed: 10–100 rpm 5.Pressure Spindle Load Range: 0.1–30 kg 6.Grinding Station Speed: 10–300 rpm 7.Polishing Station Speed: 10–300 rpm 8.Sample Holder: Φ160 mm, accommodates up to 5 samples 9.Conveyor: 1650×300 mm for loading and unloading sample trays 10.Main Dimensions: Height 2.6 m × Width 2.6 m × Depth 2.6 m |

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Logistics: