Fully Automatic Metallographic Grinding and Polishing System

1. The metal polishing grinder can automatically complete the sampling, grinding, polishing, and cleaning processes, significantly saving labor and handling up to 6 samples simultaneously.

2. The metal polishing grinder is equipped with a touch-screen human-machine interface, supporting program setting and storage for convenient operation.

3. The metal polishing grinder has a built-in database of various material preparation methods, supporting applications for multiple materials including metals, ceramics, rock samples, and electronic components.

- Shenyang Kejing

- Shenyang, China

- 44 working days

- 10 sets

- Information

Introduction of the lab metal polishing grinder:

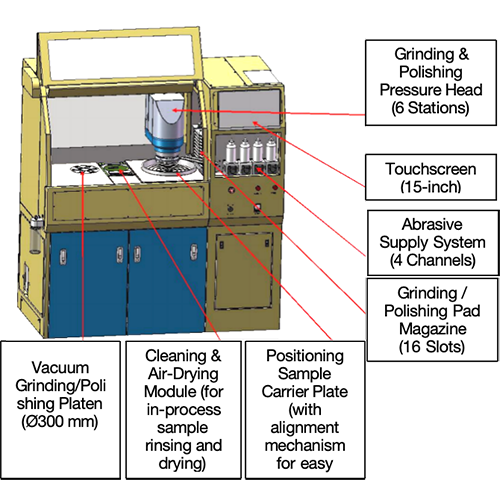

The UNIPOL-1220M lab metal polishing grinder integrates a positioning sample holder, grinding and polishing unit, cleaning unit, and feeding unit. It enables a fully automated process from sample preparation, grinding, cleaning, polishing, to final cleaning. Through the touchscreen interface, various process parameters of the lab metal polishing grinder can be precisely set and stored, supporting one-button start-up to ensure consistency and high efficiency in processing each batch of samples. The lab metal polishing grinder can also be optionally linked with an automatic mounting machine to achieve fully automated operation from mounting to grinding, polishing, and cleaning, further improving overall sample preparation efficiency. The UNIPOL-1220M metallographic grinder polisher is widely applicable to repetitive and consistent experiments on various materials such as metals, ceramics, rock samples, and electronic components, and is especially suitable for research institutions and industrial enterprises requiring material research, quality inspection, and batch sample preparation.

Technical parameters of the metallographic grinder polisher:

| Product Name | UNIPOL-1220M Automatic Metallographic Grinding and Polishing System |

Specifications of Metallographic grinder polisher | UNIPOL-1220M |

| Installation Requirements of Metallographic grinder polisher | 1. Water source requirements: Clean water source with stable water pressure in the range of 0.3–0.4 MPa. 2. Air source requirements: Clean and dry air source with a pressure of not less than 0.7 MPa and a filtration accuracy of 5 microns. 3. Ventilation requirements: The equipment installation environment must have good ventilation to ensure air circulation. |

| Main Parameters of Metallographic grinder polisher | 1. Sample Diameter: Ø25mm (Other specifications can be customized upon request) 2. Grinding Disc Diameter: Ø300mm 3. Number of Samples Processed at One Time: 6 4. Grinding and Polishing Head Rotation Speed: 10–60 rpm 5. Grinding and Polishing Pressure per Sample: 10–50 N 6. Grinding and Polishing Disc Rotation Speed: 50–300 rpm 7. Grinding and Polishing Pad Capacity: 16 8. Abrasive Supply Types: 4 groups 9. Cleaning Method: Ultrasonic cleaning 10. Dimensions: 1650mm × 800mm × 1750mm |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. |

Main features of the lab metal polishing grinder:

• The lab metal polishing grinder has an automatic sample handling function, and can automatically change grinding papers and polishing pads of different grit sizes during the grinding and polishing process.

• The laboratory metallographic grinding and polishing machine features pneumatic single-point pressure technology, ensuring even force application and consistent grinding.

• The upper and lower plate rotation speeds of the laboratory metallographic grinding and polishing machine are independently adjustable, with a low-speed, high-torque design to adapt to different process requirements.

• Air pressure can be precisely adjusted through a throttle valve, flexibly adapting to different material samples.

• The laboratory metallographic grinding and polishing machine can be equipped with multiple dispensing devices, which can be flexibly combined as needed.

• The entire machine of the laboratory metallographic grinding and polishing machine uses a painted steel plate casing, resulting in a robust and durable structure.

• The metallographic grinder polisher uses ultrasonic cleaning and air drying modules to effectively remove residues and ensure cleanliness between processes.

Technological Strength and Brand Heritage:

We are deeply committed to the research and manufacturing of cutting-edge equipment in the field of materials science, possessing a profound technological foundation. Our full range of equipment has been exported to various countries, including top laboratories and leading universities both domestically and internationally, as well as various research institutions. Shenyang Kejing is a benchmark brand in the field of materials preparation and analysis, leading the market in both market share and customer reputation.

Unlike other assembly factories, our company has a complete R&D team. For special materials or specific size requirements, we can also provide customized services from design to development.

Our equipment undergoes various precision tests before leaving the factory, ensuring the stability and accuracy of each device under high-load operation.

Additionally, if you are hesitant before purchasing, you can contact us for sample testing (we accept sample shipments). If you are satisfied with the final results, you can then decide to purchase.