4 Heads Vacuum Arc Melting System

AM-400 Four-Arc Source Melting Furnace

- Shenyang Kejing

- Shenyang, China

- 44 working days

- 10 sets

- Information

Product Introduction

The SP-AM-400 Four-Arc-Source Melting Furnace is specifically designed for melting refractory metals and their alloys, such as tungsten (W), molybdenum (Mo), zirconium (Zr), hafnium (Hf), tantalum (Ta), niobium (Nb), titanium (Ti), rhenium (Re), and beryllium (Be).

With its four independent arc sources, the SP-AM-400 provides superior heating efficiency, uniform temperature distribution, and stable melting performance. It is ideally suited for research and production applications requiring precise control of melting conditions in the preparation of high-purity or high-melting-point metal alloys.

Technical Parameters

Product Name | SP-AM-400 Four-Arc Source Melting Furnace |

| Product Model | SP-AM-400 |

Installation conditions | This equipment is required to be used at a temperature of 25℃±15℃, and a humidity of 55%Rh±10%Rh. 1. Water: The equipment is equipped with a self-circulating cooling water machine (filled with pure water or deionized water) 2. Electricity: AC380V 50Hz, must have good grounding 3. Gas: The equipment chamber needs to be filled with argon gas (purity 99.99% or more), and argon gas cylinders are required (with Ø6mm double ferrule joints) and pressure reducing valve 4. Workbench: floor type, area for installation: 2.5M×1M 5. Ventilation device: needed |

Major parameters | 1. Equipment ultimate vacuum: 8×10-4 Pa 2. Equipment power: <60kW 3. Equipment working pressure: -0.5MPa 4. System vacuum leak rate: 5.0×10-7 Pa.l/s 5. Pumping speed: pumping from the atmosphere to 7×10-3Pa≤30min. 6. Maintain the vacuum degree: the vacuum degree of the vacuum chamber shall not be lower than 10Pa after 12 hours of shutdown 7. Melting crucible: φ100×15mm, smelting 300g 8. Sample stage speed: 1 to 20 rpm, continuously adjustable · In order to ensure the safe use of the equipment, system detection and protection functions are adopted, such as: water shortage and undervoltage detection and protection, strong power phase sequence detection and protection, temperature detection and protection, vacuum system detection and protection, etc. 9. Melting Temperature: Up to 3500 °C |

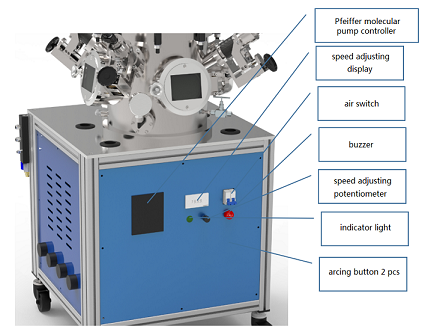

Product specification | 1. After the filling is completed, turn on the power switch of the equipment and adjust the crucible speed (1~20 rpm). 2. Operate the SPD/Pfeiffer HICube80 molecular pump unit to evacuate to 10-3Pa, close the manual flapper/buffer valve, and open the manual valve to charge the pressure to -0.03MPa. 3. Turn on the welding machine, adjust the current of the argon arc welding machine, and press the arcing buttons (2 pcs).

|

Standard Accessories

No. | name | specification (model) | qty |

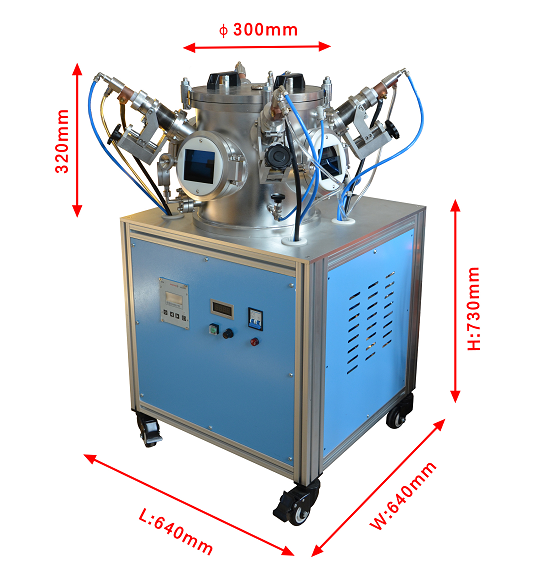

1 | Main Vacuum Chamber | Φ300×320 | 1 set |

2 | Bench Bracket | 640×640×730 | 1 set |

3 | Molecular Pump Set | HICube80 | 1 set |

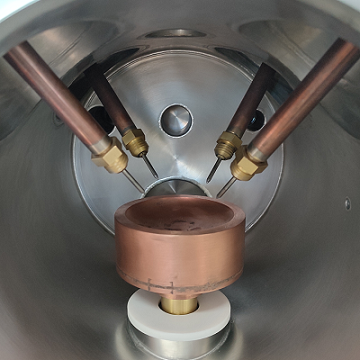

4 | Rotary Melting Crucible | One cavity of 100×15 | 1 set |

5 | Lifting Water-Cooling Electrode | 4mm W-needle | 4 sets |

6 | Sampling Door with Observation Window | 100 | 3 pcs |

7 | Manual 1/4 Ferrule Needle Valve | - | 2 pcs |

8 | Argon-Arc Welding Machine | WSM-6302 | 2 sets |

9 | High Vacuum Manual Flapper/Buffer Valve | GD-J63B(LF) | 1 set |

10 | Circulating Water Cooling Machine | KJ(CW)-6200 | 1 set |

11 | Pressure Gauge | -0.1~0.15Mpa | 1 set |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics