1100℃ Vacuum Lab High Temperature Box Furnace VBF-1200X-H8

1. Our laboratory vacuum furnace features a large-diameter Φ200mm quartz furnace chamber, combining the advantages of large-batch sintering in a box furnace with the atmosphere/vacuum heating capabilities of a tube furnace;

2. The laboratory vacuum furnace offers high efficiency, energy saving, and precise temperature control. It is coated with an imported high-temperature coating, significantly reducing energy loss and enabling rapid heating.

3. The laboratory vacuum furnace is equipped with a stainless steel water-cooled flange and a precision vacuum sealing system, supporting both flowing atmosphere and vacuum environments (vacuum degree can reach <10-5 torr with a high-vacuum unit). This high temperature lab furnace is suitable for various scientific research and industrial applications such as metal annealing and quality testing.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of High Temperature Lab Furnace:

The horizontal vacuum high temperature lab furnace VBF-1200X-H8 uses resistance wires as heating elements, features a double-layer shell structure and 50-segment program temperature control, and a K-type thermocouple. The furnace chamber of the high temperature lab furnace is made of high-purity alumina fiber material. The maximum temperature can reach 1100°C, with a continuous working temperature of 1000°C and a temperature control accuracy of ±1°C. The high temperature lab furnace has the advantages of uniform temperature field, low surface temperature, fast heating and cooling speed, and energy saving. It is a suitable product for high-temperature sintering, metal annealing, and quality testing in universities, research institutes, and industrial enterprises.

Main Features of High Temperature Laboratory Furnace:

• The high temperature laboratory furnace has an extra-large diameter quartz furnace chamber and a vacuum sealing flange system, which can be used as a box furnace for sintering large quantities of samples, and can also quickly heat samples under flowing atmosphere and vacuum conditions.

• The furnace chamber of the high temperature laboratory furnace uses high-purity alumina lightweight material, greatly reducing energy loss. The inner furnace chamber surface is coated with an imported American high-temperature alumina coating, which improves the heating efficiency of the high temperature laboratory furnace and extends the service life of the instrument.

Technical Specifications of high temperature laboratory furnace:

| Product Model | 1100℃ Vacuum high temperature laboratory furnace VBF-1200X-H8 |

Working Principle of high temperature lab furnace | • The heating furnace of high temperature lab furnace uses electric current to heat the heating elements inside the furnace. A solid-state relay is used for circuit control, and a temperature sensor (thermocouple) detects the temperature inside the furnace. The temperature detected by the thermocouple is fed back to the temperature control instrument. • The intelligent temperature controller can set the heating process (heating rate). The instrument receives the furnace temperature signal fed back by the thermocouple and uses PID control to output a suitable voltage signal. The solid-state relay receives the output signal from the instrument and controls its on/off time to regulate and stabilize the furnace temperature, allowing the high-temperature furnace to heat up according to the heating process set by the temperature controller. |

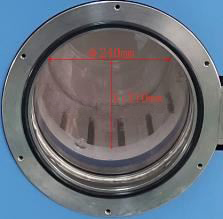

| Technical Parameters of laboratory vacuum furnace | • Rated Power of laboratory vacuum furnace: 4KW • Voltage of laboratory vacuum furnace: AC 220V, 50Hz • Heating Zone Dimensions: Φ240*210mm

• Maximum Operating Temperature of laboratory vacuum furnace: 1100°C (≤30min) Working Temperature: 1000°C • Recommended Heating Rate: ≤10℃/min • Heating Element: Resistance wire (molybdenum-doped iron-chromium-aluminum alloy) |

| Chamber Dimensions | • Quartz chamber: Φ200 × 340 mm

|

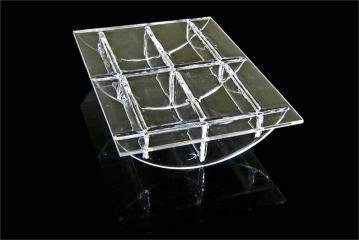

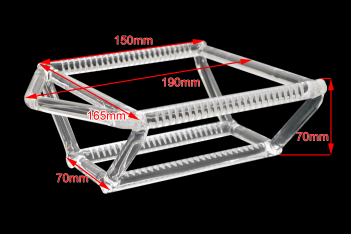

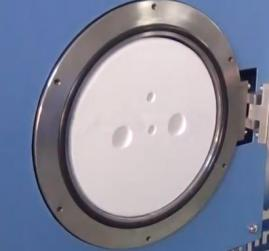

| Quartz Sample Platform | • Standard configuration includes an 8″ quartz sample platform for annealing samples.

• An optional quartz wafer boat is available for annealing wafers up to 6″ in diameter.

|

| Temperature Control System of laboratory vacuum furnace | • Intelligent temperature controller • 50-segment programmable temperature control • K-type thermocouple • Temperature control accuracy: ±1℃ • Optional PC-based temperature control software |

| Product Specifications | Dimensions: 560mm (L) x 600mm (W) x 710mm (H)

Weight: Approximately 60kg |

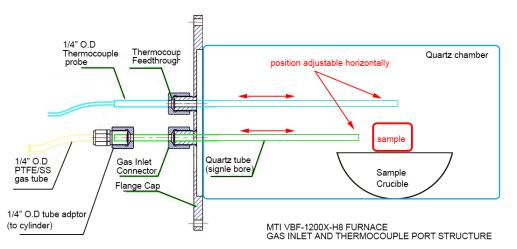

| Vacuum Flange | • Stainless steel water-cooled flange assembly with two quick-connect ports. All seals are made with silicone O-rings. • A mechanical pressure gauge is mounted on the flange, with a range of -0.1 to 0.15 MPa (digital vacuum gauge optional). • The gas inlet is a G1/4 stainless steel nozzle connector, and the outlet is a KF25 vacuum interface. The equipment can quickly heat samples under flowing atmosphere and vacuum conditions.

• Standard configuration includes one drilled refractory foam block. An optional K-type thermocouple can be inserted into the furnace chamber through the quick-connect port on the flange to monitor the temperature uniformity of the equipment.

• Vacuum level: 10⁻² torr (using a mechanical pump) • For higher vacuum levels (<10⁻⁵ torr), domestic or imported high-vacuum pump systems are available as an option. |

| Water Cooling System (Optional) | • Model: CW-3000 • Operating Voltage: AC 208-240V, 50/60Hz • Operating Current: 0.9A • Inlet/Outlet Outer Diameter: Φ10mm copper nozzle • Water Flow Rate: 10L/min • Water Tank Capacity: 9L • Equipment Dimensions: 470*270*370mm (LxWxH) |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. |

Over 20 years of dedicated development, providing "one-stop" complete solutions:

A complete closed loop from sample preparation to analysis: Unlike single equipment suppliers, since our establishment in 2000, we have developed hundreds of products covering cutting, grinding, polishing, coating, mixing, pressing, sintering (such as the high-temperature furnaces you see), and analysis.

Hassle-free and efficient purchasing experience: Whether it's crystals, ceramics, metals, or biomaterials, customers can obtain all the equipment and consumables needed from "sample pretreatment" to "high-temperature heat treatment" and "property analysis" from us in one go, ensuring compatibility between experimental equipment and significantly reducing procurement and maintenance costs.