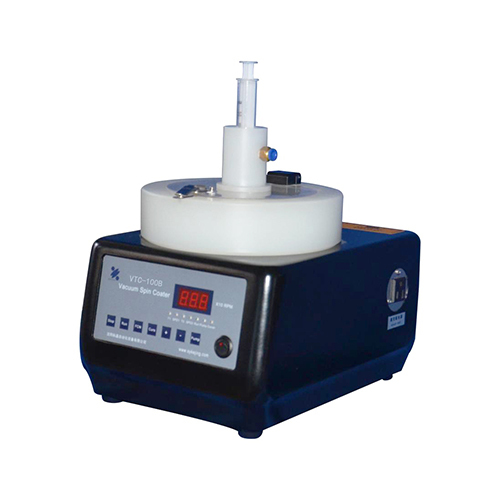

10000 RPM Ultra-Hi Speed Spin Coater

VTC-100PAX Vacuum Spin Coater is a high-performance precision glue leveling machine. It adopts advanced design concept and cooperates with precise motion control system for high-precision and high-uniformity glue dispensing operation. 6 groups of programs can be stored, each program can reach 9 steps. All operating parameters can be easily set on the device, such as speed, acceleration, rotation time, etc.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Product Introduction

The VTC-100PAX Vacuum Spin Coater is designed for surface coating preparation in semiconductor processes, crystals, optical discs, lithography, and related applications. As a high-performance precision spin coater, the VTC-100PAX incorporates an advanced design concept combined with a precise motion control system, enabling high-accuracy and high-uniformity coating operations.

The system can store 6 programs, each containing 9 sequential stages. Each stage’s parameters can be independently set, allowing the coater to gradually accelerate to its maximum speed. This ensures uniform thin-film formation on the sample surface while minimizing material waste.

The chamber is made of polypropylene, featuring excellent heat resistance, electrical insulation, and high wear-resistance performance. The chamber itself cannot be evacuated; during operation, the sample is firmly held on the substrate holder via a vacuum chuck connected to an external vacuum pump through the rotor shaft gas line. This setup allows easy operation and convenient sample loading/unloading, with the chuck vacuum reaching up to –0.08 MPa.

The rotating spindle is driven by a high-speed brushless DC motor, offering low noise, minimal vibration, smooth operation, high reliability, strong adaptability, and simple maintenance. The motor starts quickly and runs stably after acceleration, ensuring consistent and uniform coating thickness.

With advantages such as simple operation, easy cleaning, and compact design, the VTC-100PAX Vacuum Spin Coater is widely used in laboratories of universities and research institutes for thin-film preparation.

Technical Parameters

Product Name | VTC-100PAX Vacuum Spin Coater | |

Product Model | VTC-100PAX | |

Installation conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around the equipment. 3. Water: The equipment is equipped with a sewage outlet 4. Electricity: Single phase: AC220V 50Hz 10A . 5. Gas: Vacuum negative pressure (vacuum pump): 0.06-0.09Mpa 6. Workbench: 800mm×600mm×700mm recommended bearing weight of more than 50kg (solid cement platform is better) 7. Ventilation device: no special requirements | |

| The main parameters | 1. Power supply interface: Power socket with insurance: AC220V 50Hz, insurance tube specification is 10A, φ5×20mm 2. Total power: ≤150W (excluding external vacuum pump) 3. Coating host cavity (material): polypropylene 4. Sample tray (suction cup): polypropylene vacuum suction cup: 1 inch (applicable to φ25 samples), 3 inches (applicable to φ76 samples) each 5. Operation mode: 6 sets of programs can be stored, each set of programs contains 9 operation stages 6. Coating speed: 500-10000rpm effective 7. Acceleration and deceleration rate: Each section of the increase and decrease speed setting range: 100-2000 rpm 8. Coating time: Each section time range: 0-999s 9. Speed stability: ±1% 10. Control mode: PCB single chip microcomputer key control LMC LCD display | |

Product Dimension and Weight | 11. Product Specifications · Dimension: 270mm (width) × 430mm (depth) × 400mm (height) · Weight: 12kg |

|

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics