In-depth Analysis of the HXQ-25-6 Six-Station Metallographic Hot Mounting Press

2026-02-04 17:11In materials science research, metal processing manufacturing, and third-party testing institutions, the preparation of metallographic samples is a crucial step before microscopic analysis. For many busy laboratories, sample mounting is often a bottleneck in efficiency. Traditional manual or single-station mounting machines are not only time-consuming but also highly dependent on the operator's skill, easily leading to inconsistent sample preparation quality and even rework in subsequent grinding and polishing steps due to human error.

Faced with current sample testing demands, laboratories urgently need a solution that can achieve "high throughput," "fully automatic," and "high consistency."

I. Core Highlights: Why Choose the HXQ-25-6 Metallographic Hot Mounting Press?

The HXQ-25-6 metallographic hot mounting press is a high-efficiency sample preparation center created by Shenyang Kejing based on years of industry experience for modern intelligent laboratories.

1. Six-station simultaneous processing, 600% efficiency increase.

This is the most impressive feature of this model. Traditional mounting machines can only process one sample at a time, and the heating, pressure holding, and cooling process usually takes 10-20 minutes. If you have 30 samples, it means the operator needs to repeatedly perform mechanical actions for more than half a day.

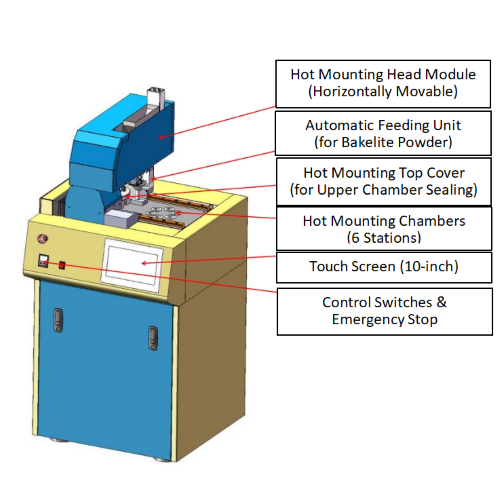

The HXQ-25-6 metallographic hot mounting press has 6 independent mounting chambers, allowing it to process up to 6 samples simultaneously. This means that your laboratory's output efficiency will increase by 6 times in the same amount of time. For companies or university laboratories undertaking a large number of testing tasks, this means significant savings in labor costs and a reduction in delivery time.

2. Fully automatic closed-loop experience with "unattended operation."

True automation is not just about pressing a button. The HXQ-25-6 achieves full-process automation from automatic feeding, automatic loading, heating, pressurizing, pressure holding, cooling, to final automatic demolding.

Automatic feeding unit: Precisely controls the dosage, reduces waste, and avoids the potential impact of dust on the operator's health.

Fully automatic operation: The operator only needs to place the samples, set the parameters, and click start to leave and do other work. No manual pressure release or mold prying is required; the equipment automatically ejects the samples after the operation is complete.

3. Perfect system integration and precise positioning.

In modern metallographic laboratories, sample mounting is often just the first step, usually followed by fully automatic grinding and polishing machines. The HXQ-25-6 boasts precise sample positioning capabilities.

It is not just a standalone device, but can also be seamlessly integrated into Shenyang Kejing or other brands' "fully automatic grinding and polishing systems." The uniform reference plane and dimensions ensure flatness and consistency in the subsequent grinding and polishing process, laying a solid foundation for high-precision microscopic analysis.

II. In-depth Analysis of Technical Details.

The HXQ-25-6 metallographic hot mounting press excels in both hardware configuration and human-machine interaction.

Intuitive Control Center: The metallographic hot mounting press is equipped with a 10-inch touchscreen. The interface design is logically clear, allowing users to adjust mounting pressure, temperature, and time according to different material characteristics (such as steel, ceramics, and composite materials). These parameters can be stored for easy recall, ensuring the traceability of experimental data.

Horizontally Moving Head Module: This design greatly simplifies the sample loading and unloading process, and also facilitates daily cleaning and maintenance of the equipment.

Safety First: The control panel integrates prominent control switches and an emergency stop button, complying with industrial safety standards. The fully enclosed metal casing effectively isolates the risk of high-temperature burns.

Key Technical Parameters at a Glance:

Product Model: HXQ-25-6.

Sample Diameter: Φ25mm (classic metallographic size, compatible with most microscope stages).

Processing Capacity: 1-6 samples per batch.

Operating Voltage: 220V 50Hz.

Operating Power: <2500W.

Equipment Dimensions: L850 * W750 * H1500mm (compact, integrated floor-standing design, saving laboratory bench space).