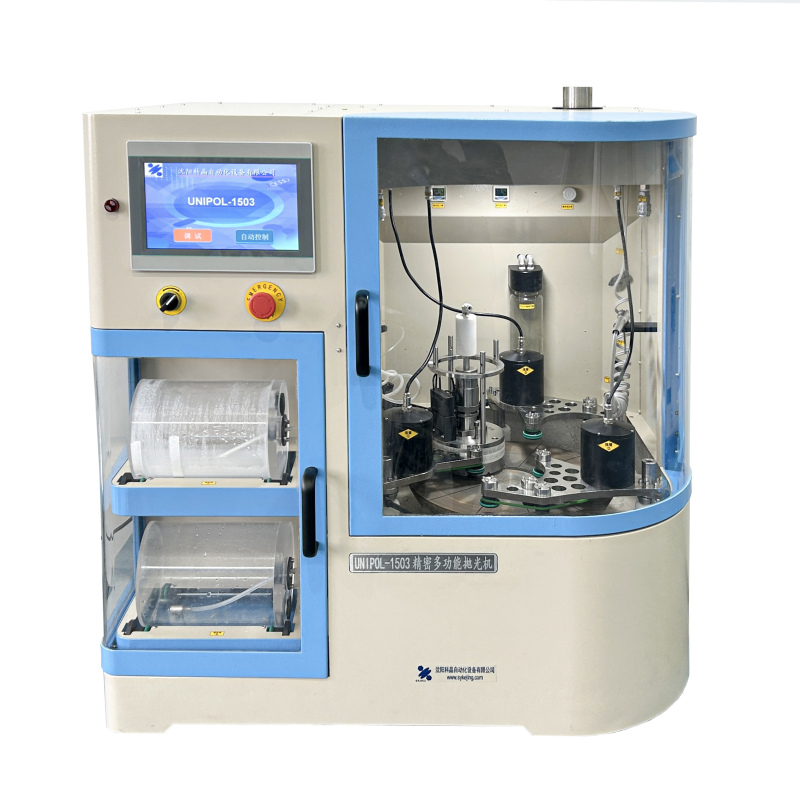

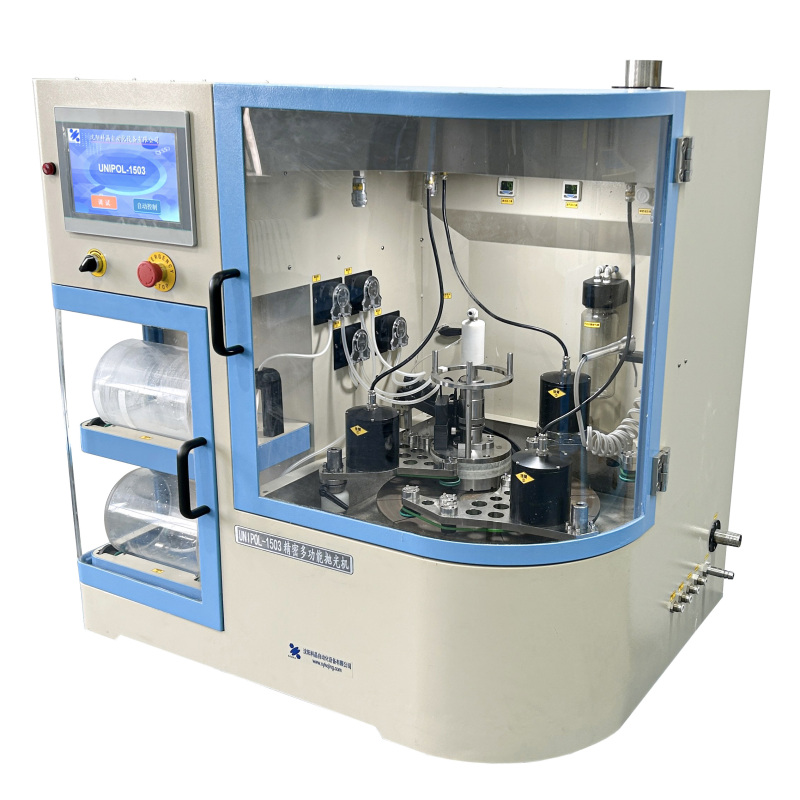

X in 1 Precision Polisher

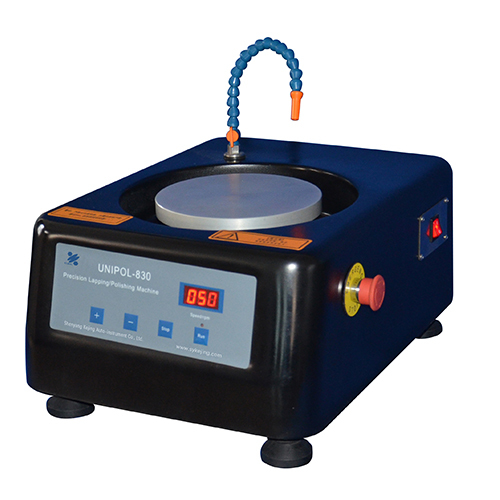

UNIPOL-1503 X in 1 Precision Polisher is equipped with three workstations. It is a desktop grinding and polishing machine that can grind and polish large-size samples. It is suitable for grinding and polishing samples of crystals, ceramics, metals, glass, rock samples, mineral samples, PCB board, infrared optical materials.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Technical Parameters

Product Name | Unipol-1503 X in 1 Precision Polisher | |

Product Model | Unipol-1503 | |

Conditions for Installation

| 1.Temperature and humidity:10-85%RH (at 25℃ no condensation) Temperature: 0-45℃ 2.No strong source and corrosive gas around the equipment 3.Water:The equipment is equipped with water inlet and outlet ports, which need to be connected to the site's tap water and drainage system 4.Power supply:Single phase:AC220V 50Hz 10A. 5.Air supply: · Air negative pressure (vacuum pump) pumping flow is not less than 70L/M · Compressed air (air compressor) working pressure: ≤ 0.2MPa 6.Auxiliary Equipment (to be purchased separately): Recommended: · HEATER-3040 or 250 heating platform · SKCH-1 Precision Thickness Gauge · SKCS-1 Air Dryer | |

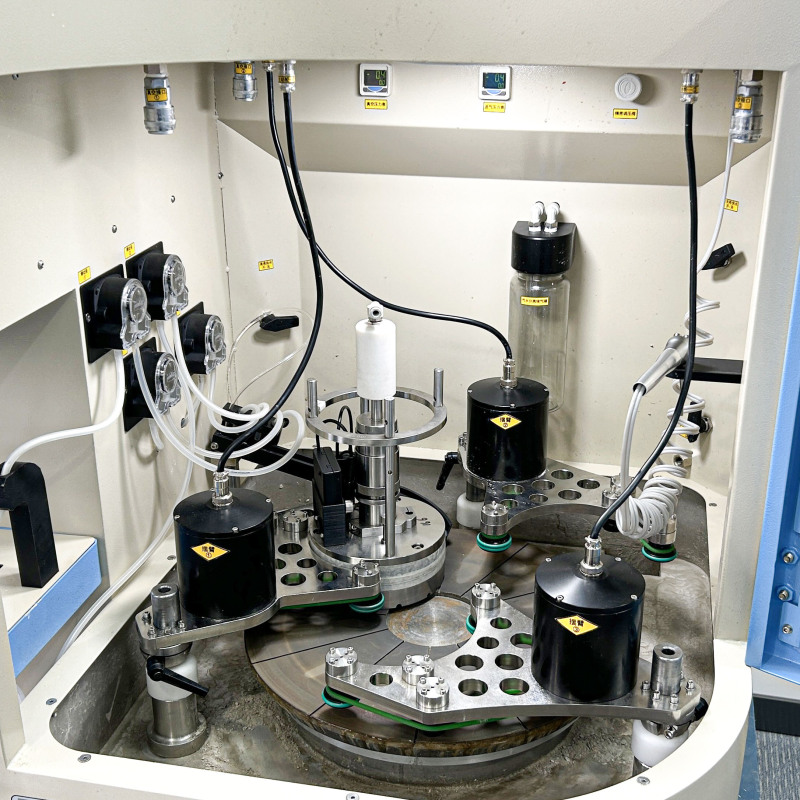

Major Parameters (Specification) | 1.Power supply:AC220V 50Hz 10A 2.Main structure:Aluminum alloy + sheet metal closed hood3.Lapping plate driving motor(Main shaft):AC servo motor 4.Lapping plate speed:10-120rpm 5.Lapping plate rotation model: One direction:anticlockwise 6.Lapping plate(mm):1 cast iron patterned disc and 1 flat aluminum disc; Disc diameter: φ381 mm. 7.Dressing Ring Specifications: Standard: 2 dressing rings; Disc diameter: φ143 mm 8.Maximum Sample Size for Grinding: 100mm/4" 9.Swing Grinding Stations: 3 stations10.Swing arm driving motor:Permanent magnet dc motor 11.Swing Arm Speed: Step speed control: 3–10 levels; Maximum swing: ≈10 times/min 12.Driving wheel driving motor:stepping motor 13.Driving wheel speed:1-300rpm(Adjustable)14.Bluetooth Precision Grinding & Polishing Controller (Robotic Arm): Standard: 1 station with vacuum adsorption sample holder (φ103 mm); additional 2 stations optional 15.Mixing/Agitation Stations: 2 stations 16.Mixing Speed: 5–30 rpm 17.Mixing container:1.4Lx2 18.Suspension Storage Bottle Capacity: 500 mL × 2 19.Dispensing Stations (Peristaltic Pump): Total 4 stations: 2 for mixing solution dispensing, 2 for suspension dispensing 20.Dispensing Pump Speed: 0.1–20 rpm 21.Exhaust System: High-speed filtered exhaust system 22.Grinding Stop Mode: Time mode / Material removal mode 23.Control mode:Integrated control,PLC program +10 inch touch screen 24.Auxiliary Functions:

| |

25.Product Dimension: · 1000mm×800mm×1050mm(Closed) · 1650mm×800mm×1050mm(Door Open) | ||

Warranty

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics