Single-Crystal Orientation Machine

DX-100 X-ray single-crystal orientation machine is a high-tech precision instrument of optical, mechanical and electrical integration, which can quickly determine the crystal plane of natural and artificial crystals. It can be used with various cutting, grinding and other processing equipment, and is an indispensable instrument for precision processing and manufacturing crystal components. X-ray single crystal orientation machine uses the principle of X-ray diffraction for orientation of crystal, silicon, germanium single crystal, lithium niobate, lithium tantalate, yttrium vanadate, laser crystal, optical fiber communication crystal, and other single crystal material. The machine is simple to operate, and is an ideal equipment for a variety of single crystal materials at scientific research institutions and factories. DX-100 X-ray sing-crystal orientation machine is equipped with a single workbench with a large pallet to meet the orientation of ingots, rods, and wafer endfaces. It is divided into upper and lower parts. It is small in size, and easy for desktop measurement, which can meet the orientation measurement of single-crystal crystals and make corresponding judgment on the quality of the crystals.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction

The DX-100 X-ray Single Crystal Orientation Instrument is a high-precision mechatronic device designed for rapid determination of crystal planes in both natural and synthetic crystals. It can be used in conjunction with various cutting, grinding, and other processing equipment, making it an indispensable tool for the precision manufacturing of crystal components.

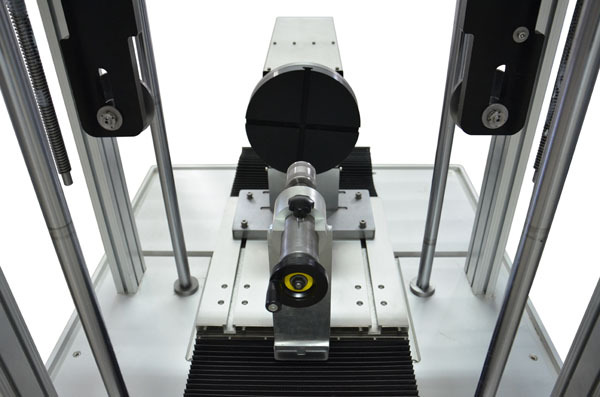

Based on the principle of X-ray diffraction, the DX-100 is capable of orienting a wide range of single crystal materials, including quartz, silicon, germanium, lithium niobate, lithium tantalate, yttrium vanadate, laser crystals, optical communication crystals, and other single crystals. The instrument features simple operation and high measurement accuracy, making it an ideal choice for research institutions and crystal manufacturing enterprises.

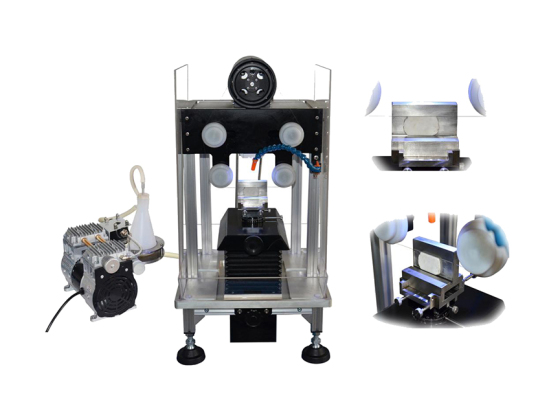

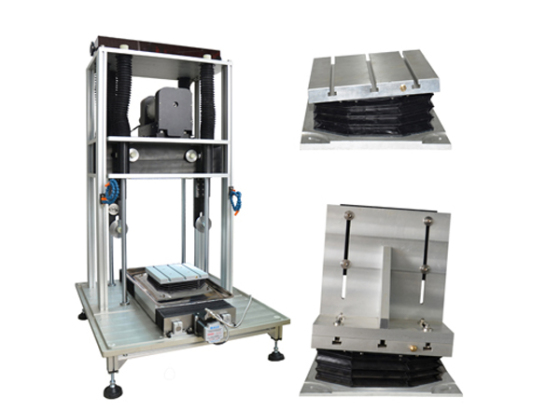

The DX-100 adopts a single worktable design equipped with a large supporting plate, suitable for orientation of crystal ingots, rods, and wafer end faces. The device consists of upper and lower modules, with a compact structure ideal for desktop use. It supports precise crystal orientation measurement and can also assess the crystalline quality of the sample.

Main Features

1. Adopt the split structure for main machine and electrical control.

2. Small in size and light in weight

Technical Parameters | |||

Product Name | DX-100 X-Ray Single-Crystal Orientation Machine | ||

Product Model | DX-100 | ||

Major Parameters (Specification) | 1. X-ray Generator Section: · X-ray Tube: Copper target, fan-cooled, with grounded anode. · Tube Voltage: 30 kV, full-voltage operation. · Tube Current: Continuously adjustable from 0–5 mA. Using a current above 2.0 mA may damage the X-ray tube and increase radiation hazards. 2. Power Supply: 3. Angle Measurement Range: · 2θ Angle: 0 to ±110° · θ Angle: 0 to +55° 4. Equipment accuracy: ±30″, reading resolution: 1″ (measured using the standard quartz plate 10T1 provided by the supplier). 5. Instrument Configuration: · Mechanical Components: Main unit, tube housing, and various mechanical accessories. · Electrical Components: Voltage stabilizer, controller, high-voltage transformer, amplifier, counter, air-cooled motor, X-ray tube, and various indicator instruments. | ||

Product Dimension | Size: main machine: 695mm×600mm×470mm electrical control box: 650mm×460mm×470mm | ||

Logistics