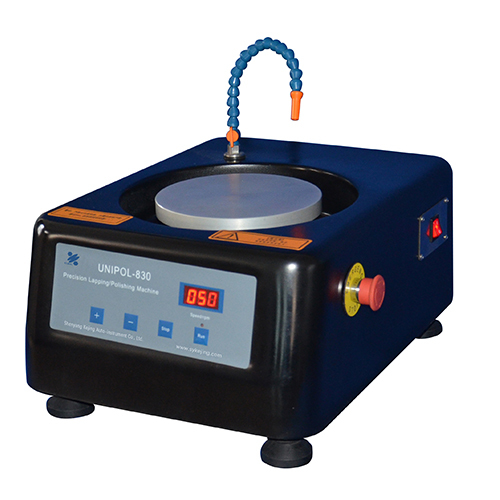

Precision Multifunctional Grinding and Polishing Machine

1. To meet customer needs, our automatic grinding and polishing machine has been expanded to three processing stations, accelerating processing and improving efficiency.

2. Our automatic grinding and polishing machine features a precise polishing controller for even more accurate processing.

3. This automatic grinding and polishing machine has undergone thousands of tests, meeting Shenyang Kejing's high standards for durability, accuracy, and safety, and has performed reliably even under extreme testing.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of the metallographic grinding and polishing machine:

The UNIPOL-2030 metallographic grinding and polishing machine features three processing stations and is a floor-standing grinder and polisher capable of grinding and polishing large samples. It is suitable for grinding and polishing crystals, ceramics, metals, glass, rock samples, mineral samples, PCBs, infrared optical materials (such as zinc selenide, zinc sulfide, silicon, and germanium crystals), refractories, and composite materials. It is an ideal grinding and polishing machine for scientific research and production experiments.

Metal polishing grinder is Equipped with a Ø508mm grinding and polishing plate, three processing stations, a precise grinding and polishing controller, and two drop feed systems, the metallographic grinding and polishing machine is ideal for thinning and polishing wafer samples (≤Ø150mm), enabling automated grinding and polishing.

Technical Parameters of the metallographic grinding and polishing machine:

| Product name | UNIPOL-2030 Precision Multi-function Metal Polishing Grinder |

| Model | UNIPOL-2030 |

| Installation requirements of metal polishing grinder | 1. Temperature and humidity: 10-85% RH (at 25°C non-condensing) Temperature: 5-45°C. 2. The area around the equipment must be free of strong vibration sources and corrosive gases. 3. Water: The equipment is equipped with an inlet and outlet. You must connect to the on-site tap water and drainage pipelines. 4. Electricity: Single-phase: AC 220V 50Hz, national standard three-pole 10A socket. A properly grounded protective conductor is required. 5. Air source: · Vacuum (vacuum pump) with a suction flow rate of at least 70L/m (standard). · Compressed air (air compressor) with a working pressure of ≤ 0.2MPa (standard). 6. Auxiliary equipment (sold separately): Recommended: (1) HEATER-3040 or 250 heating platform. (2) SKCH-1 Precision Thickness Gauge. (3) SKCS-1 Blow Dryer |

| Main parameters of metal polishing grinder | 1. Power supply of metal polishing grinder: Three-pole power plug: AC 220V 50Hz 10A |

| 2. Grinding disc drive motor (spindle): AC servo motor | |

| 3. Grinding disc speed: 10-90 rpm | |

| 4. Grinding disc rotation: Unidirectional: Counterclockwise | |

| 5. Grinding disc specifications: One cast iron faceplate and one flat aluminum disc; Disc outer diameter: φ508mm | |

| 6. Carrying Plate Specifications: Standard: Two flat loading plates, outer diameter: Φ160mm | |

| 7. Repair Ring Specifications: Standard: Two repair rings, outer diameter: Φ195mm | |

| 8. Maximum sample size: 6" (customizable up to 8") | |

| 9. Swinging Grinding Stations: Three | |

| 10. Swing Arm Drive Motor: Permanent Magnet DC Motor | |

| 11. Swing Arm Support Swing Speed Range: 15-30 (reference speed: 5.5-13.5 times/minute). The swing arm can be folded upward for easy cleaning of the grinding plates and replacement of the sample carriers. | |

| 12. Swing Arm Drive Motor: Stepper Motor | |

| 13. Swing Arm Upper Drive Wheel Speed: 30-90 rpm | |

| 14. Precision Grinding and Polishing Controller (Robot): Standard: One station with vacuum suction function, carrying plate: Ø162mm (two additional stations optional). | |

| 15. Mixing and Stirring Stations: Two | |

| 16. Mixing Speed: 5-30 rpm | |

| 17. Mixing Tank Capacity: 1.4 L x 2 | |

| 18. Suspension Storage Bottle Capacity: 500 mL x 2 | |

| 19. Drip Stations (Peristaltic Pump): 4 in total: 2 for mixing and 2 for suspension | |

| 20. Drip Pump Speed: 0.1-20 rpm | |

| 21. Exhaust System: High-speed filtered exhaust system. | |

| 22. Grinding and Stop Modes: Time Mode/Grinding and Polishing Volume Mode. | |

| 23. Control and Display: Integrated control: 10-inch touchscreen display. | |

24. Auxiliary Functions: · Sample cleaning nozzle, vacuum filter, exhaust gas exhaust function, and protective gas recharge port. · Bluetooth: Real-time data feedback after Bluetooth connection. | |

25. Specifications of automatic grinding and polishing machine: · Dimensions: Approximately 1300 mm × 1100 mm × 1800 mm | |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. |

About us:

This metal polishing grinder, along with all of our products, has undergone thousands of experiments and technical iterations. Shenyang Kejing's equipment has reached internationally advanced levels of precision, stability, and safety.

Our metal polishing grinders are sold both domestically and internationally, earning acclaim from numerous universities and research institutions.

We approach every test with a rigorous scientific approach, ensuring that each metal polishing grinder becomes a reliable partner in our customers' laboratories.

Shenyang Kejing is making Made in China a solid foundation for global scientific research.