Multi-station Tube Furnace

1. Horizontal Tube Furnace is independently produced by our company and its quality is higher than that of its peers.

2. Horizontal Tube Furnace has passed CE certification and its quality is guaranteed.

3. Horizontal Tube Furnace is small in size and is designed for small samples.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of Horizontal Tube Furnace:

GSL-1100X-S Multi-Zone Tube Furnace is a CE-certified small-diameter tube furnace (1~2" diameter), which is designed for preparing small samples. The maximum temperature can reach 1100℃. The standard configuration includes stainless steel sealing flanges and quartz tubes. The Multi-Zone Tube Furnace can be used immediately after powering on. With a 50-segment programmable precision temperature controller, the Multi-Zone Tube Furnace can set the temperature rise and fall program according to different customer needs. The temperature control accuracy is ±1℃. The Multi-Zone Tube Furnace furnace body can be placed vertically or horizontally to meet different applications, such as VSL, CVD, and other quenching tests.

The high temperature tube furnace uses resistance wire as the heating element, K-type thermocouple temperature measurement and 518P temperature controller for automatic temperature control, with high temperature control accuracy. In addition, this high temperature tube furnace also has a vacuum device, which can work in a variety of atmospheres, greatly improving the product's range of use. This high temperature tube furnace has the advantages of high operating temperature, high-precision temperature control, simple operation, and convenient maintenance. The furnace can be widely used in metallurgy, machinery, light industry, colleges and universities, scientific research departments, etc. In addition, the performance of high temperature tube furnace can reach the standards of similar foreign products.

Main features of the Horizontal tube furnace:

The Horizontal Tube Furnace is small in size and can be placed anywhere for use;

The operation of the Horizontal Tube Furnace is simple, which reduces the training time of personnel.

The Horizontal Tube Furnace has powerful functions and beautiful appearance, and is widely used.

Technical parameters of High temperature tube furnace:

| Product model | 1100℃ Multi-station tube furnace GSL-1100X-S |

| Main parameters of High temperature tube furnace | · Power supply: AC 220V 50HZ · Power: 1.2KW · Max temperature: 1100℃ (<30min) · Working temperature: 1000℃ · Recommended heating rate: ≤10℃/min · Heating zone length: 300mm · Thermocouple: K type · Heating element: O Cr27Al7MO2 (molybdenum-doped iron-chromium aluminum alloy) · Furnace size: φ80*330mm |

| Furnace structure of High temperature tube furnace | · The Multi-Zone tube furnace is made of high-purity alumina fiber material to minimize energy loss. · Height-adjustable stainless steel shell. · Three knobs on the back can be adjusted to flexibly change the vertical position of the furnace (from the control box platform to the lower end of the furnace). · A variety of configurations are suitable for various heat treatment needs.

|

| Furnace tube size and material | · High-purity quartz tube, size (optional): φ1″*600mm/φ50*600mm. · Standard alumina tube plug is used to prevent heat radiation from the internal tube (the tube plug must be fully inserted into the furnace chamber before heating). · Quartz tube plug can be purchased separately to improve the vacuum and cleanliness inside the furnace tube.

|

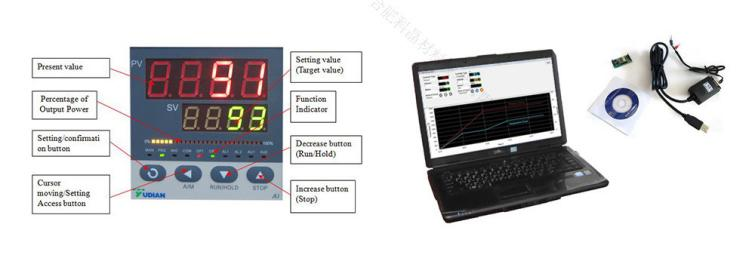

| Temperature control system of High temperature tube furnace | · Includes a YD858P temperature controller; · PID automatic temperature control system; · Intelligent 50-segment programmable control; · Built-in overheat protection and thermocouple fault alarm; · Temperature control accuracy: ±1℃; · Default DB9 PC communication connection port; · Passed MET certification; · Optional computer temperature control software (for YD858P series controller) to control the heating curve and export data; · Optional European control instrument, temperature control accuracy can reach ±0.1℃.

|

| Flange and optional accessories | ·Two stainless steel flanges are available: ·2" default flange with 1/4" pagoda fitting, 1/4" tube pass-through (for 1/4" OD thermocouple insert) and KF25 vacuum connector. ·1" flange without thermocouple plug. ·Optional: ·Baffle valve can be purchased to connect to vacuum system (Figure 1). ·For faster and better vacuum, we recommend stainless steel bellows (Figure 2). ·You can consider ordering quick connect flanges, but it costs extra (Figure 3). ·Furnaces can be ordered with digital vacuum gauge and mechanical pump system (Figure 4).

|

| Sealing flange and vacuum connection | Stainless steel sealing flange (1/4" hose connector on the left side, KF-25 connector on the right side, Figure 1). ·Standard 1/4" pagoda fitting with needle valve. ·In order to use high pressure gas, you can replace the standard pagoda fitting with a 1/4" hose connector (Figure 2). ·Optional: To achieve high vacuum, Replace the standard pagoda nozzle with a KF25 adapter.

1 inch flange. 2 inch flange. · Optional vacuum connection: · The company's imported anti-corrosion digital vacuum display gauge has a measurement range of 3.8x10-5 to 1125 Torr. No coefficient conversion is required due to different types of measured gases. (Figure 3). · KF25 stainless steel bellows (Figure 4). · KF25 quick-release clamp (Figure 5).

|

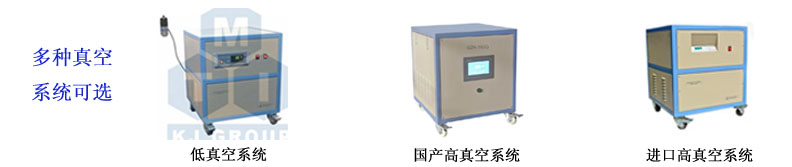

| Vacuum system (optional) | · The vacuum degree of the double-vane mechanical pump can reach 10-2torr. · If you want to obtain a higher vacuum degree (10-5torr or higher), you can choose a domestic or imported high vacuum unit.

|

| Dimensions of Multi-Zone tube furnace | 260×380×400 mm (D x H x W); Weight: 45Kg |

| Weight of Multi-Zone tube furnace | 45Kg |

| Certification of Multi-Zone tube furnace | · This Horizontal tube furnace has passed the CE certification Certificate number: M.2021.206.C67996 · If the customer pays the certification fee, the company guarantees that a single device will pass the German TUV certification or CAS certification |

| Warranty period of Multi-Zone tube furnace | One-year warranty period, lifetime maintenance · Special tips: 1. Consumables such as heating elements, quartz tubes, sample crucibles, etc. are not included. 2. Damage caused by the use of corrosive gases and acidic gases is not covered by the warranty. |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. |

Technical advantages of Shenyang Kejing:

The company has a high-level R&D team, which continuously upgrades technology and develops new products, applies for a number of independent intellectual property rights, and provides customers with personalized equipment customization services. The company has professional experimental configuration and senior sample preparation technicians. After years of intensive cultivation, it has established a complete sample preparation process to provide researchers with systematic sample preparation guidance.